| Lithium Zirconate Sputtering Targets | |

| Product No | NRE-43252 |

| CAS No. | NA |

| Formula | Li6Zr2O7 |

| Molecular Weight | 153.1 |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

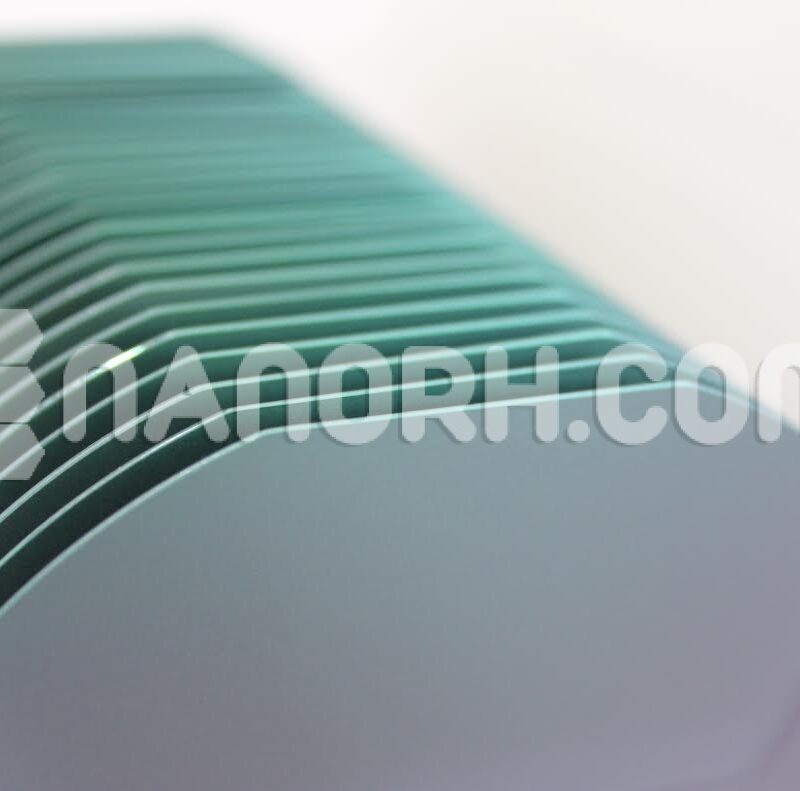

Lithium Zirconate Sputtering Targets

Introduction

Lithium Zirconate Sputtering Targets is a lithium-based ceramic compound known for its unique properties, including high thermal stability, ionic conductivity, and chemical resistance. These characteristics make it particularly valuable in various applications, including solid-state electrolytes for batteries and other energy storage systems. Lithium zirconate is also being explored for its potential in nuclear waste management due to its ability to immobilize radioactive materials.

Sputtering Targets made from lithium zirconate are used in thin film deposition processes, enabling the fabrication of high-quality films for various electronic and energy applications.

Applications

Solid-State Batteries:

Electrolyte Material: Lithium zirconate is primarily utilized as a solid electrolyte in lithium-ion batteries. Its high ionic conductivity enhances battery efficiency and safety compared to traditional liquid electrolytes.

Thin Film Batteries:

Sputtered lithium zirconate films can be employed in thin film batteries, which are critical for compact and lightweight electronic devices, such as wearables, sensors, and portable electronics.

Nuclear Waste Immobilization:

Due to its ability to stabilize radioactive isotopes, lithium zirconate is being investigated for applications in nuclear waste management, providing a safe method for immobilizing hazardous materials.

Electrochemical Sensors:

The ionic conductivity of lithium zirconate makes it suitable for use in electrochemical sensors, enabling the detection of lithium ions and other chemical species.

Ceramics and Coatings:

Lithium zirconate can be used in advanced ceramics and protective coatings, improving thermal stability and mechanical properties in various industrial applications.