| Lanthanum zirconate Powder | |

| Product No | NRE-11309 |

| CAS No. | 12031-48-0 |

| Formula | La2Zr2O7 |

| Molecular Weight | 572.2548 g/mol |

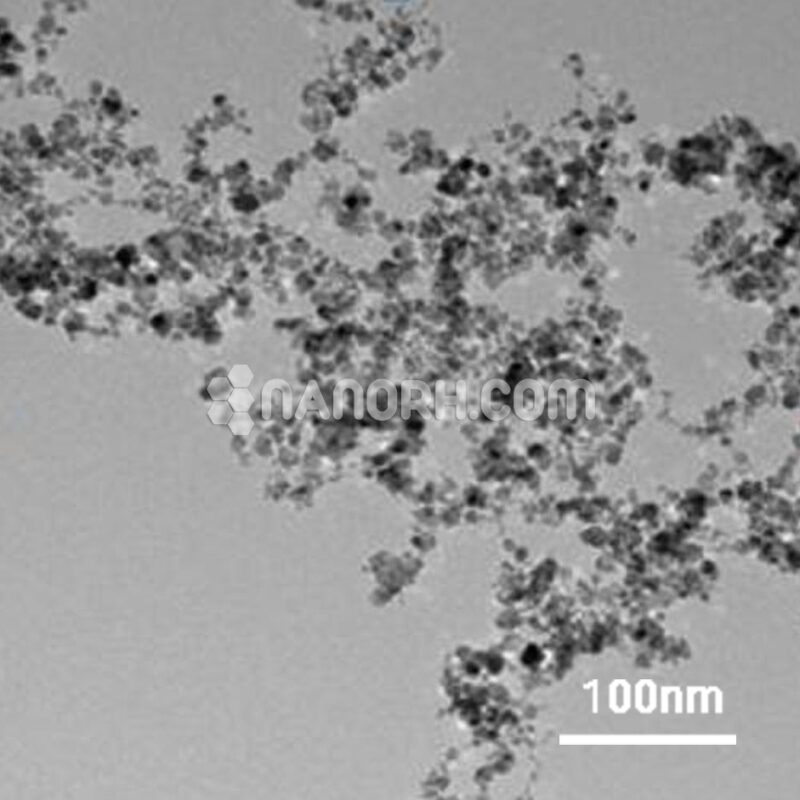

| APS | <40 μm(can be customized) |

| Purity | 99.9% |

| Density | NA |

| Color | Grey |

| Melting Point | NA |

| Boiling Point | NA |

Lanthanum zirconate Powder

Lanthanum zirconate powder, which is a compound of lanthanum and zirconium, has several unique properties that make it useful in various applications. Some of the common applications of lanthanum zirconate powder include:

Thermal barrier coatings: Lanthanum zirconate powder is often used in the production of thermal barrier coatings due to its high melting point and thermal stability. These coatings are applied to components in gas turbines, jet engines, and other high-temperature environments to protect them from heat damage.

Solid oxide fuel cells (SOFCs): Lanthanum zirconate powder is used in the fabrication of electrolyte materials for SOFCs. These fuel cells can convert chemical energy directly into electrical energy with high efficiency, and lanthanum zirconate helps enhance the performance and durability of the cells.

Oxygen sensors: La2Zr2O7 powder is utilized in the production of oxygen sensors, which are used to measure the oxygen content in gases. These sensors find applications in automotive exhaust systems, industrial processes, and medical devices.

Catalyst supports: La2Zr2O7 powder can be employed as a catalyst support material in various chemical reactions. Its high surface area and thermal stability make it suitable for use in catalytic converters, petrochemical processes, and other industrial applications.

Electronic ceramics: La2Zr2O7 powder can be used in the production of electronic ceramics, such as dielectric materials, due to its high dielectric constant and low dielectric loss. These ceramics are used in electronic components and devices, including capacitors and resonators.

High-temperature crucibles and refractory materials: La2Zr2O7 powder can be used to manufacture crucibles and refractory materials for high-temperature applications in industries such as metallurgy, glass manufacturing, and semiconductor production.