| Iron Silicon Alloy Powder | |

| Product No | NRE-9019 |

| CAS No. | 8049-17-0 |

| Formula | Fe-Si |

| Molecular Weight | 83.9305 g/mol |

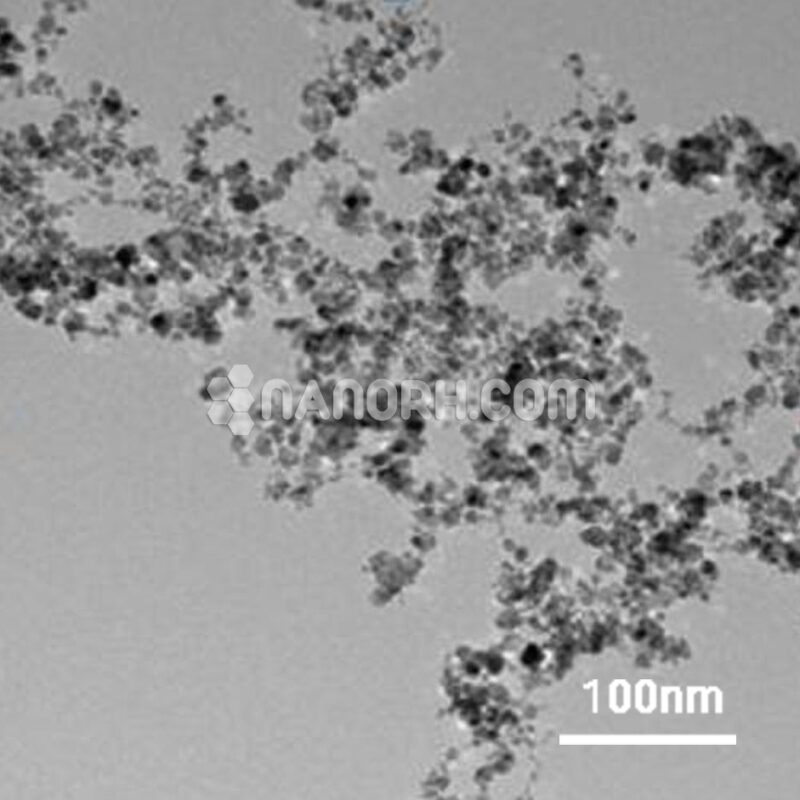

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | 6.7 g/cm3 |

| Color | Gray |

| Melting Point | 1212-1630 °C |

| Boiling Point | NA |

Iron Silicon Alloy Powder

Electrical and Magnetic Applications:

Electrical Steel: One of the most common uses of Iron Silicon alloys is in the production of electrical steel, which is used in transformers, motors, generators, and inductors. The enhanced magnetic properties and low eddy current losses of Iron Silicon alloys make them ideal for use in magnetic cores and laminations for these devices.

Magnetic Shielding: Due to the alloy’s ability to enhance magnetic performance, it is used in magnetic shielding for electronic devices that need protection from external magnetic fields, such as in communication equipment and sensitive measurement instruments.

Automotive Industry:

Motors and Alternators: Iron Silicon alloys are used in the production of motors, alternators, and other electrical components in vehicles. Their magnetic properties make them ideal for applications that require high-efficiency magnetic components in electric and hybrid vehicles.

High-Temperature Automotive Parts: Due to their high-temperature strength, Iron Silicon alloys are also used in automotive components like engine parts, turbochargers, and exhaust systems that are exposed to extreme temperatures.

Industrial Machinery:

Gears and Bearings: The improved wear resistance of Iron Silicon alloys makes them suitable for high-performance gears, bearings, and machine components that are subjected to significant friction and abrasion in industrial machinery.

Heat Exchangers: The thermal stability and corrosion resistance of Iron Silicon alloys make them ideal for heat exchangers and furnace linings in industries like petrochemical and metallurgical processing.

Energy Industry:

Power Generation: Iron Silicon alloys are widely used in power generation applications, particularly in the manufacturing of transformer cores and electrical generators. The alloy’s magnetic properties contribute to improved energy efficiency in transformers and motors, essential for power distribution and electricity generation.

Wind Turbines: Iron Silicon alloys are also employed in wind turbine generators where low-loss magnetic materials are critical for maintaining high efficiency and performance under varying loads.