Iron Alloy Powder For 3D Printing

The main application of 3D printing metal powder;

Aerospace

Molds

Automotive

Medical instruments

Military industry

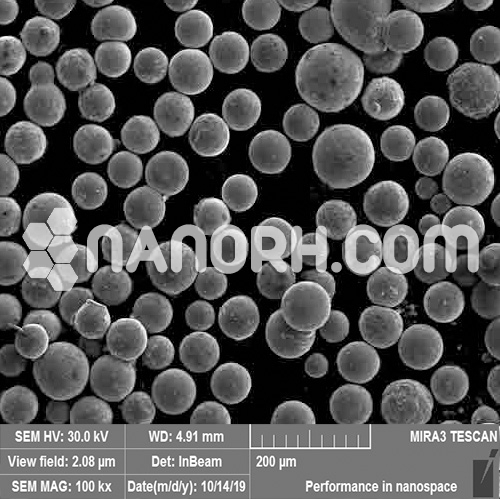

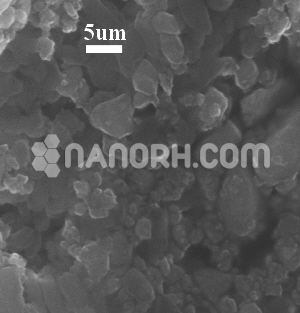

| Product No. | Iron Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60005 | NRE-SS316L | Cr 16-18,Ni 10-14, Mo 2-3, Fe Bal. | 0.05-0.1 | 4.6-5.2 | 15-45um, 15-53um, 45-150um, D50 10-15um, D50 1-2um, D50 0.5-1um. |

| NRE-SS304L | Cr 18-20,Ni 8-10, Fe Bal. | ||||

| NRE-SS17-4PH | Cr 15-17.5 Ni 3-5, Cu 3-5, Al Bal. | ||||

| NRE-18Ni300 | Ni 18-19, Mo 4.6-5.2, Co 8.5-9.5,Ti 0.5-0.8, Fe Bal. | ||||

| NRE-H13 | Cr 4.7-5.5, Mo 1.1-1.7, V 0.8-1.2 Si 0.8-1.2, Fe Bal. | 4.5-5.0 | |||

| NRE-M2 | Cr 3.8-4.4, Mo 4.5-5.5, W5.5-6.7, V 1.7-2.2, Fe Bal. | 4.8-5.5 |

Iron Alloy Powder For 3D Printing

Applications

Automotive Industry:

Engine Components: Iron alloy powder for 3d printing such as steel, are used to create engine blocks, cylinder heads, and turbocharger components. The alloys’ high strength, durability, and thermal stability are key in automotive engines, which are subjected to extreme conditions.

Transmission and Suspension Parts: Components like gears, shafts, and suspension brackets can be made from iron alloy powders, benefiting from their wear resistance and toughness.

Custom Parts for Performance Vehicles: 3D printing allows the production of custom-designed parts, which is particularly useful for motorsports and high-performance vehicles where precision and weight reduction are essential.

Aerospace Industry:

Structural Components: Iron alloys like steel and stainless steel are used to 3D print structural components such as brackets, supports, and housings that require high strength-to-weight ratios and resistance to fatigue.

Heat Exchangers and Thermal Management: Iron alloys are suitable for parts involved in heat dissipation, such as heat exchangers and cooling components in aircraft engines.

Landing Gear and Other Load-Bearing Components: Components in aerospace, such as landing gear and engine mounts, benefit from the high tensile strength and durability of iron alloys under high-stress conditions.

Energy Sector:

Power Generation: Iron alloy powders are commonly used for producing components like turbine blades, valves, and heat exchangers in power plants. The ability to withstand high temperatures and pressure makes these alloys a critical material in power generation.

Oil and Gas Equipment: Parts used in offshore and underground applications, like drill bits and valve bodies, benefit from the corrosion resistance and mechanical strength of iron alloys, particularly stainless steel.

Tooling and Manufacturing:

Molds and Dies: Iron alloy powders, particularly tool steels, are used to produce molds, dies, and other tooling parts used in manufacturing processes like injection molding, casting, or stamping. The ability of iron alloys to withstand wear and heat makes them ideal for tooling applications.

Cutting Tools: Iron alloys, especially tool steels, are also used for producing cutting tools like drills, end mills, and chisels that require a combination of hardness, toughness, and wear resistance.