Highly Conductive Carbon Black & Graphene & Carbon Nanotubes Mixed 20wt% in Water Dispersion

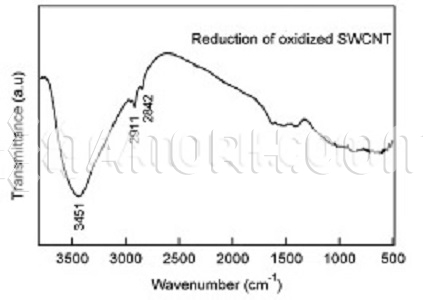

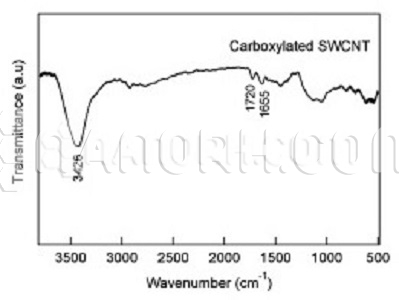

Effectively improve the electrical conductivity, thermal conductivity and mechanical properties; Effectively enhance tensile strength, hardness and elastic modulus characteristics. Also, Higher electrode conductivity and stronger electrode mechanical strength and adhesive attraction; The product is composed of high electric conductive CNTs and graphene and highly conductive carbon black nanopowder. The carbon black nanoparticles can not only prevent dispersed CNTs and graphene from reagglomerating, but also exhibit synergetic effect with CNTs and graphene.

| Highly Conductive Carbon Black & Graphene & Carbon Nanotubes Mixed 20wt% in Water Dispersion | |

| Product No | NRE-39017 |

| CAS No. | NA |

| Purity | > 97% |

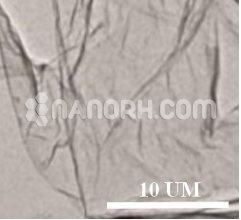

| Average Diameter | >55 nm |

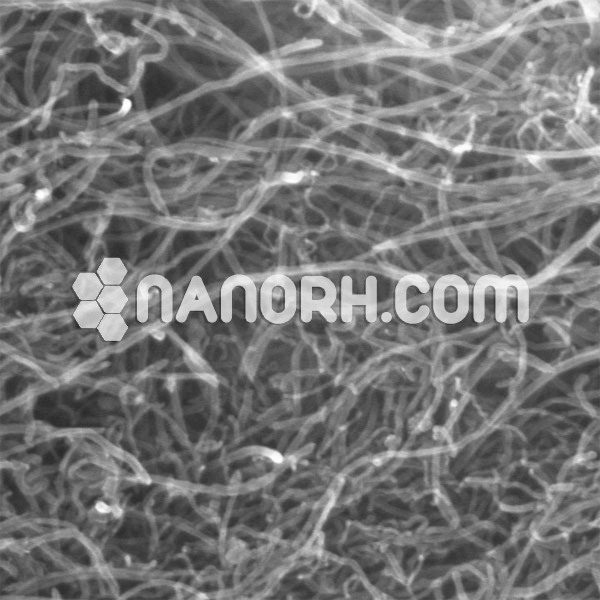

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | > 60 m2/g (BET) |

| Tap Density | 0.12 g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | >100 s/cm |

Highly Conductive Carbon Black & Graphene & Carbon Nanotubes Mixed 20wt% in Water Dispersion Nanotubes

Introduction

Highly conductive carbon black, graphene, and carbon nanotubes (CNTs) mixture at 20wt% in water dispersion refers to a composite material where the three forms of carbon—carbon black, graphene, and carbon nanotubes—are dispersed in an aqueous solution at a weight concentration of 20%. This dispersion allows for easy handling and application in various coatings, inks, and composite materials. The 20wt% concentration is specifically chosen to ensure that the dispersion retains high conductivity, while still being manageable for various industrial applications.

Applications

The combination of carbon black, graphene, and carbon nanotubes in a water dispersion offers several unique advantages, such as flexibility, cost-effectiveness, environmental friendliness, and easy processing. These properties make the material ideal for use in a wide range of applications across various industries. Below are the primary application areas:

Conductive Inks and Printed Electronics

Printed Electronics: The primary application of a 20wt% carbon black, graphene, and CNT water dispersion is in the creation of conductive inks used for printed electronics. These inks are printed onto substrates such as paper, plastics, and flexible films to create printed circuits, antennas, RFID tags, and sensor networks. The composite mixture enhances the conductivity of the ink, while maintaining the flexibility and cost-effectiveness needed for large-area applications like smart packaging or wearable electronics.

Flexible Electronics: The mixture of graphene, CNTs, and carbon black in a water-based dispersion enables the fabrication of flexible circuits that can be bent, stretched, and molded into different shapes. These conductive inks can be used for applications in wearable devices, smart textiles, and flexible displays.