| Hafnium Nitride Nanoparticles | |

| Product No | NRE-5101 |

| CAS No. | 25817-87-2 |

| Formula | HfN |

| Density | 13800 kg/m-3 |

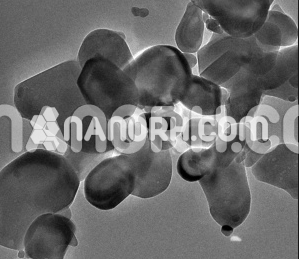

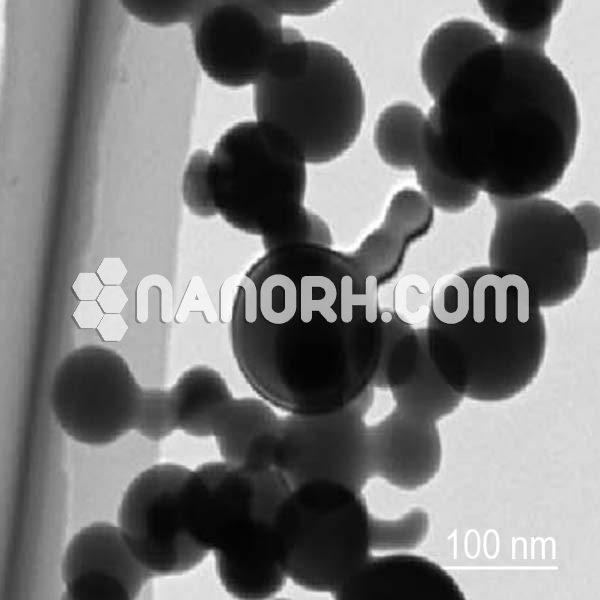

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Form | Powder |

| Molecular Weight | 192.496 g/mol |

| Certificate Of Analysis | |

| Hf | 92.7% |

| N | 7.2% |

| O | 0.02% |

| Ni | 0.03% |

| Co | 0.02% |

| Fe | 0.01% |

| S | 0.01% |

Hafnium Nitride Nanoparticles

Applications

Aerospace and Defense:

High-Temperature Coatings: Due to its extremely high melting point and thermal stability, hafnium nitride nanoparticles are ideal for use in high-temperature coatings in aerospace and defense industries. These coatings are used on components such as rocket nozzles, turbine blades, and jet engines, where they protect parts from extreme heat and oxidation.

Thermal Protection Systems: In space exploration, HfN nanoparticles are used in the development of thermal protection systems (TPS) for spacecraft. These systems prevent damage from the intense heat generated during re-entry into Earth’s atmosphere or when operating in outer space.

Electronics and Semiconductors:

High-Performance Electronic Devices: Hafnium nitride nanoparticles are being explored for use in semiconductors and electronic devices, particularly in components that need to operate at high temperatures or in harsh environments. HfN’s excellent electrical conductivity and thermal stability make it an ideal candidate for use in high-power transistors, sensors, and resistors.

Gate Dielectrics in Transistors: Similar to other hafnium-based materials, HfN is being investigated for its potential as a gate dielectric in MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors). The high dielectric constant and thermal stability of HfN nanoparticles can improve the performance of transistors in modern integrated circuits, especially for devices operating under extreme conditions.

Conductive Thin Films: HfN nanoparticles can be used to create conductive thin films for microelectronics and optical devices. These films can be integrated into devices such as solar cells, LEDs, and photo detectors.

Cutting Tools and Wear-Resistant Coatings:

Hard Coatings: Hafnium nitride is known for its hardness and abrasion resistance, making it a useful material in the production of cutting tools and machinery parts that require enhanced durability. HfN nanoparticles can be used to create hard coatings on tools such as drills, milling cutters, and dies to improve their lifespan and performance.

Wear-Resistant Coatings: The hardness and wear resistance of hafnium nitride nanoparticles also make them suitable for coatings in applications where high wear resistance is critical, such as in automotive components, aerospace parts, and industrial machinery.