| Hafnium Aluminium Oxide Sputtering Target | |

| Product No | NRE-43062 |

| CAS No. | NA |

| Formula | HfAlO2 |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | 9 10x Ω-m |

| Thermal Expansion | NA |

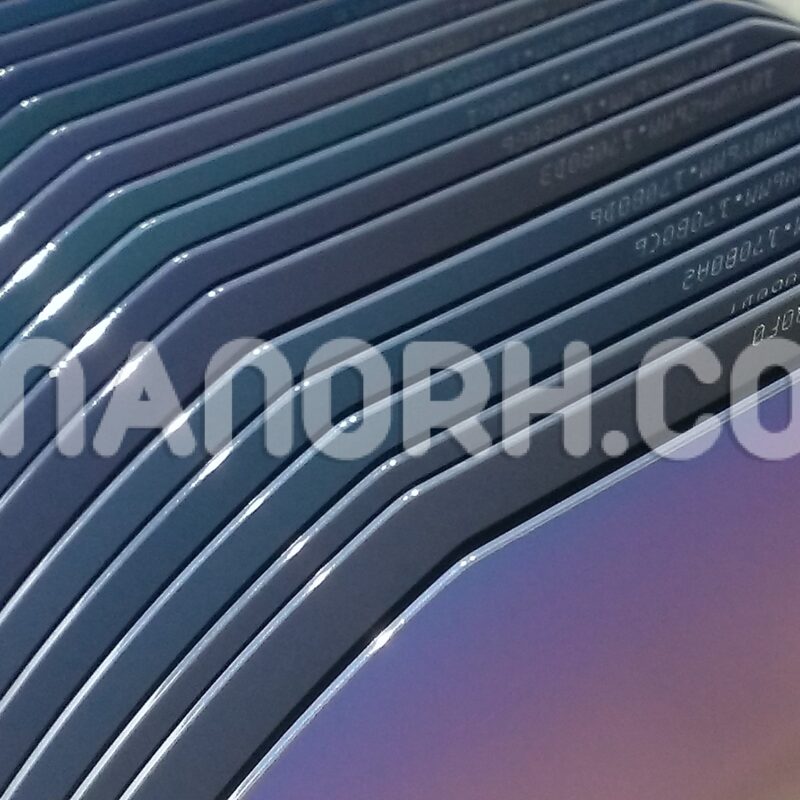

Hafnium Aluminium Oxide Sputtering Target

Introduction

Hafnium aluminum oxide (HfAlO2) sputtering targets are materials composed of a combination of hafnium oxide (HfO₂) and aluminum oxide (Al₂O₃). These targets are used in the sputtering process, a physical vapor deposition (PVD) technique that allows for the deposition of thin films onto various substrates. HfAlO2 is recognized for its unique properties, including high dielectric constant, excellent thermal stability, and good electrical insulation.

The integration of hafnium and aluminum oxides results in enhanced performance characteristics, making HfAlO2 suitable for a variety of advanced applications in electronics and optoelectronics.

Applications

Semiconductor Devices: HfAlO2 is widely used as a high-k dielectric material in metal-oxide-semiconductor (MOS) devices, helping to reduce leakage currents and improve gate capacitance.

Gate Dielectrics:

FinFET Technology: In advanced FinFET (Fin Field-Effect Transistor) devices, HfAlO2 serves as a gate dielectric, enhancing performance while minimizing power consumption.

Memory Devices:

Non-Volatile Memory: HfAlO2 is utilized in resistive random-access memory (ReRAM) and phase-change memory (PCM) applications, where its properties facilitate improved switching behavior.

Optoelectronics:

Optical Coatings: HfAlO2 films can be applied in optical coatings, enhancing the performance of lenses and mirrors by providing high refractive indices and transparency.

Thin-Film Transistors (TFTs):

Display Technologies: HfAlO2 is employed in the fabrication of TFTs for LCD and OLED displays, offering excellent electrical insulation and performance.

Protective Coatings:

Durability Enhancement: HfAlO2 coatings provide wear and corrosion resistance, making them suitable for applications in harsh environments.

Microelectromechanical Systems (MEMS):

Piezoelectric Devices: HfAlO2 films can be integrated into MEMS devices to enhance performance in sensors and actuators.

Catalysis:

Catalytic Coatings: Due to its chemical stability, HfAlO can be used in catalytic applications, enhancing the efficiency of chemical reactions.