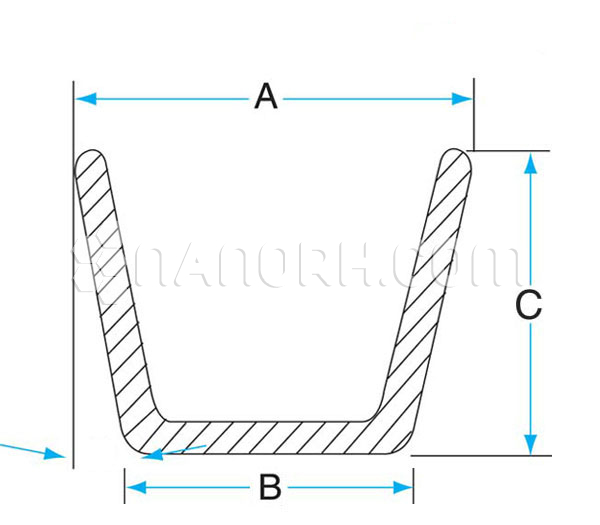

| GRAPHITE Crucibles | |

| Product No | NRE-47002 |

| CAS | 7782-42-5 |

| Purity | >99.9% |

| Apparent Porosity | ≤ 30 % |

| Capacity | 5ml |

| Electric Resistivity | 13 µΩm |

| Ash | 0.06 % |

| Density | 2.2 g/cm³ |

| Melting Point | 2730 °C |

| Boiling Point | NA |

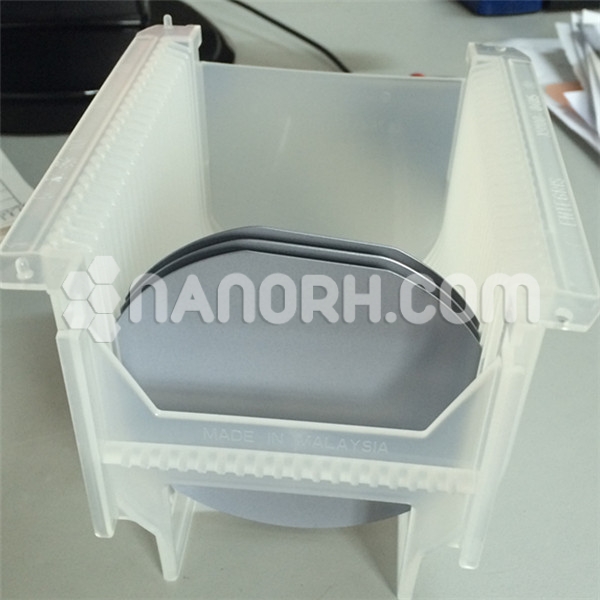

GRAPHITE Crucibles

Introduction:

GRAPHITE crucibles are high-performance containers made from high-purity GRAPHITE. Renowned for their excellent thermal conductivity, chemical resistance, and ability to withstand extreme temperatures, GRAPHITE crucibles are essential in various high-temperature applications. Their inert nature ensures that they do not react with molten metals or other materials, making them ideal for processes where contamination must be minimized.

Applications

Metallurgical Processes:

Melting and Casting: Widely used for melting non-ferrous metals and alloys, such as gold, silver, and aluminum. Their ability to maintain high temperatures allows for efficient melting and minimal oxidation.

Foundry Work:

Utilized in foundries for pouring molten metal, where they help achieve consistent results and precise temperature control.

Material Processing:

Employed in the production of ceramics, glass, and advanced materials, facilitating processes that require high thermal conductivity and stability.

Laboratory Applications:

Commonly used in laboratories for various analytical techniques, including as containers for high-temperature reactions and materials testing.

Sintering:

Applied in the sintering of metal and ceramic components, where uniform heating is crucial for achieving desired properties.

Nuclear Applications:

Sometimes used in nuclear chemistry for handling radioactive materials due to their stability and resistance to radiation.

High-Temperature Research:

Utilized in research settings for experiments involving high temperatures and extreme conditions, especially in materials science.

Jewelry Making:

Used in the jewelry industry for melting and casting precious metals, allowing for high precision and control over the melting process.

Reviews

There are no reviews yet.