| FeCoTaZr Sputtering Target | |

| Product No | NRE-43052 |

| CAS No. | NA |

| Formula | FeCoTaZr |

| Molecular Weight | NA |

| Purity | 3N5 |

| Density | NA |

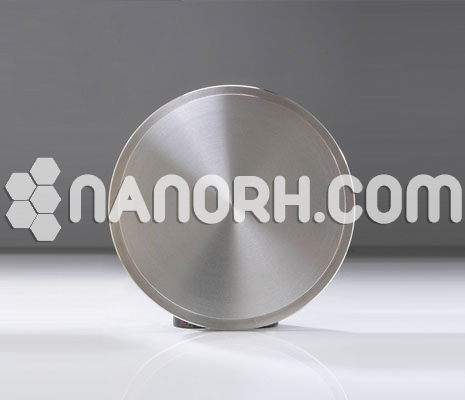

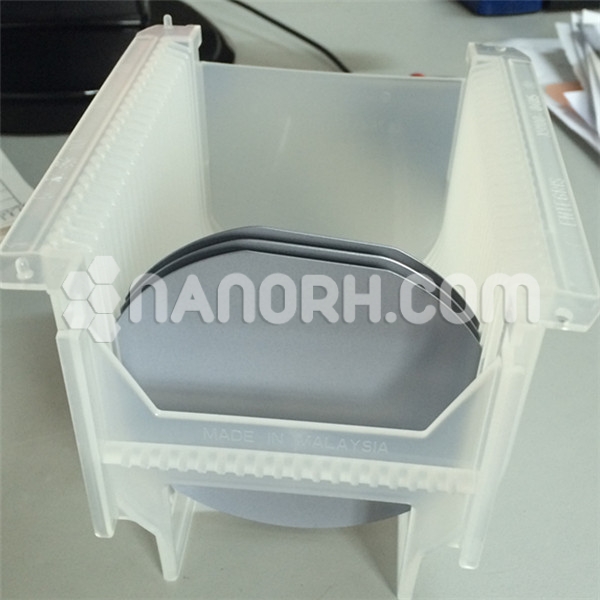

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

FeCoTaZr Sputtering Target

Applications:

Magnetic Thin Films:

Magnetic Sensors: The combination of iron, cobalt, and the stabilizing elements tantalum and zirconium makes this alloy suitable for producing high-performance magnetic sensors.

Magnetic Recording Media: The alloy’s properties are advantageous for thin films used in magnetic recording media such as hard drives and magnetic tapes.

Soft Magnetic Materials:

Transformers and Inductors: FeCoTaZr alloys are used in soft magnetic materials for transformers and inductors. The alloy’s magnetic properties, combined with its stability, make it ideal for applications where low core loss and high permeability are essential.

High-Performance Magnetic Devices:

Actuators and Motors: The alloy can be used in high-performance magnetic devices, including actuators and motors, where high magnetic responsiveness and durability are needed.

Magnetic Shielding:

Electromagnetic Interference (EMI) Shielding: Due to its magnetic properties, the alloy can be used in EMI shielding applications to protect electronic devices from electromagnetic interference.

High-Temperature Applications:

Durable Magnetic Components: Tantalum and zirconium enhance the high-temperature stability of the alloy, making it suitable for applications that involve elevated temperatures or harsh environments.

Amorphous or Nanocrystalline Materials:

Advanced Magnetic Materials: The alloy can be used to create amorphous or nanocrystalline magnetic materials, which have unique magnetic properties such as reduced hysteresis losses and high magnetic permeability.

Research and Development:

Material Science: The FeCoTaZr alloy is valuable in R&D for exploring new magnetic materials and developing advanced technologies with tailored magnetic and physical properties.