| Fe-Cr-Co Alloy Nanoparticles | |

| Product No | NRE- 2019 |

| CAS No. | 7439-89-6/7440-47-3/7440-48-4 |

| Formula | FeCrCo |

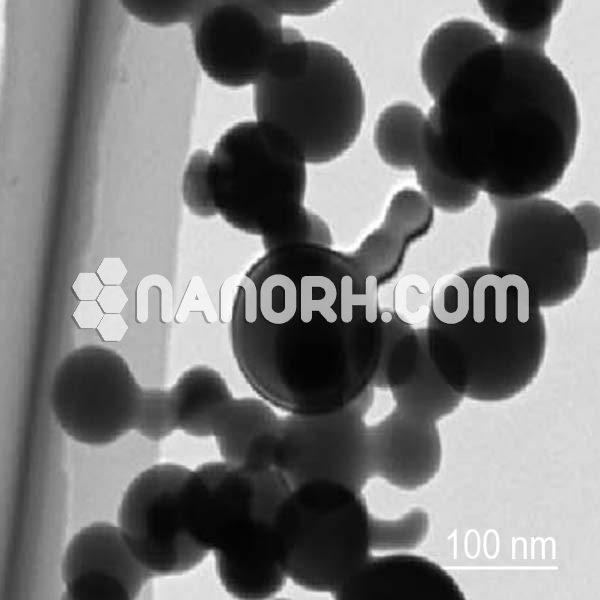

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey |

| Molecular Weight | 166.7743 g/mol |

| Density | NA |

| Melting Point | NA |

| Boiling Point | NA |

Fe-Cr-Co Alloy Nanopowder

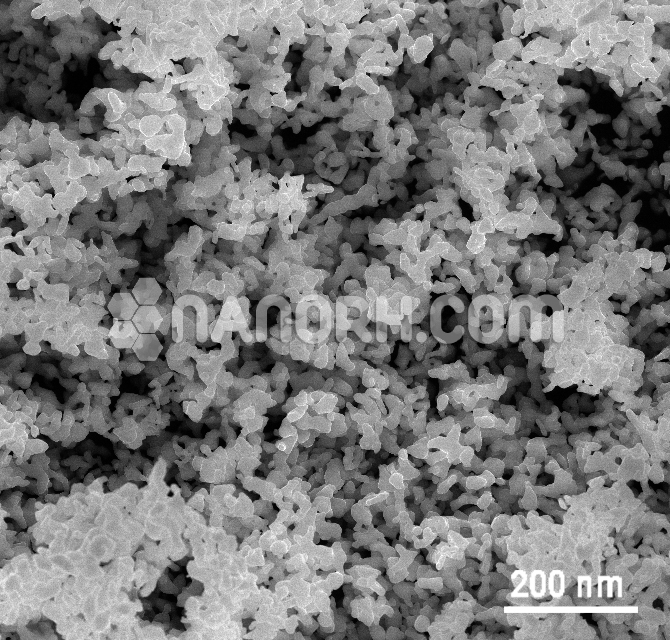

Fe-Cr-Co Alloy Nanopowder is a specialized material that combines three fundamental elements—iron (Fe), chromium (Cr), and cobalt (Co)—into an alloy that exhibits a unique set of properties that are significantly enhanced when the alloy is in nanopowder form. When reduced to the nanoscale (typically below 100 nanometers), the material exhibits significant improvements in various physical, chemical, and mechanical properties compared to its bulk counterpart, making it suitable for a wide range of advanced technological and industrial applications.

This alloy’s nanopowder form has gained substantial attention due to its superior magnetic, corrosion-resistant, and wear-resistant properties, making it highly valuable in diverse fields, including electronics, energy storage, catalysis, biomedicine, and materials science. The alloy itself is a combination of iron, chromium, and cobalt, where each element contributes its distinct properties:

Iron (Fe): Known for its strong magnetic properties and good mechanical strength, iron is the backbone of the alloy and imparts good structural integrity.

Chromium (Cr): Chromium enhances the alloy’s corrosion resistance, making it ideal for harsh environments. It also contributes to the formation of a strong protective oxide layer on the surface of the material.

Cobalt (Co): Cobalt is added primarily for its exceptional magnetic properties, including high magnetic saturation and coercivity, which makes Fe-Cr-Co alloys particularly valuable in magnetic applications.

In the nanopowder form, the size reduction results in an exponential increase in the surface area-to-volume ratio, which in turn leads to enhanced chemical reactivity, greater mechanical strength, and improved catalytic efficiency. This characteristic is especially beneficial for applications where high performance in small spaces is critical, such as in nanoelectronics, energy storage, and catalysis.

The synthesis of Fe-Cr-Co alloy nanopowder typically involves advanced techniques such as mechanical alloying, chemical vapor deposition (CVD), and sol-gel processes.