| Cu-In-S Alloy Nanoparticles | |

| Product No | NRE- 2011 |

| CAS No. | 7440-50-8/7439-89-6/7704-34-9 |

| Formula | Cu-In-S |

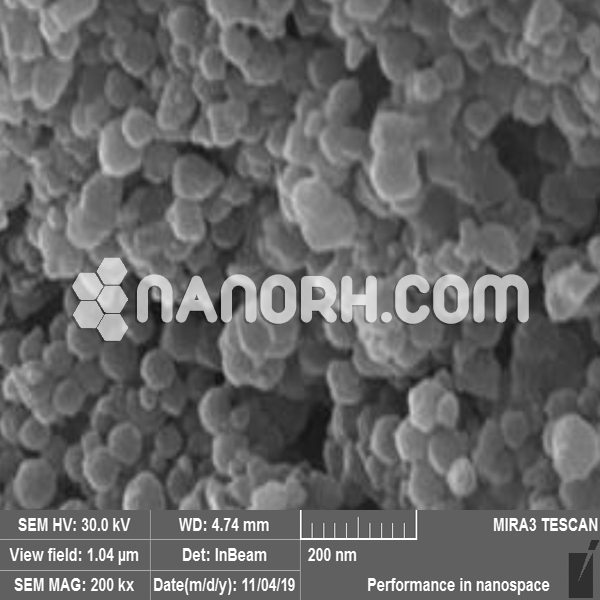

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey-black |

| Molecular Weight | 210.429 g/mol |

| Density | 1.5-1.8 g/cm³ |

| Melting Point | 1145°C |

| Boiling Point | 1354°C |

Cu-In-S Alloy Nanopowder

Applications

Photovoltaic and Solar Energy Applications:

Thin-film Solar Cells: Cu-In-S alloy nanoparticles are widely used in thin-film solar cells because of their high absorption efficiency and ability to convert solar energy into electricity. CuInS₂ has an ideal bandgap that allows for the efficient absorption of sunlight, particularly in solar panels where flexibility and lightweight properties are essential.

Alternative to Silicon-Based Solar Cells: Compared to traditional silicon solar cells, Cu-In-S-based solar cells can be more cost-effective to produce and are highly efficient in converting light energy into electricity, making them a promising material for next-generation solar energy technologies.

Optoelectronic Devices:

LEDs and Photodetectors: Due to their excellent optical properties, Cu-In-S alloy nanoparticles are used in the manufacturing of light-emitting diodes (LEDs), photodetectors, and laser diodes. The tunable bandgap enables them to emit light in different wavelengths, including infrared and visible light, which is useful for a wide range of optoelectronic applications.

Display and Communication Systems: Cu-In-S nanoparticles are also integrated into displays and communication devices because of their ability to efficiently convert electrical signals into light or detect light with high sensitivity.

Catalysis:

Photocatalysis: Cu-In-S nanoparticles exhibit strong photocatalytic activity, especially under visible light. They are used in photo-catalytic applications like water splitting to generate hydrogen, offering a clean and renewable energy source. The material’s ability to absorb visible light makes it highly effective for solar-driven catalytic processes.

Chemical Catalysis: Cu-In-S nanoparticles are also effective in traditional chemical catalysis such as hydrogenation and dehydrogenation reactions. Their high surface area and reactivity increase the rate of catalytic reactions, especially in green chemistry and sustainable chemical production.