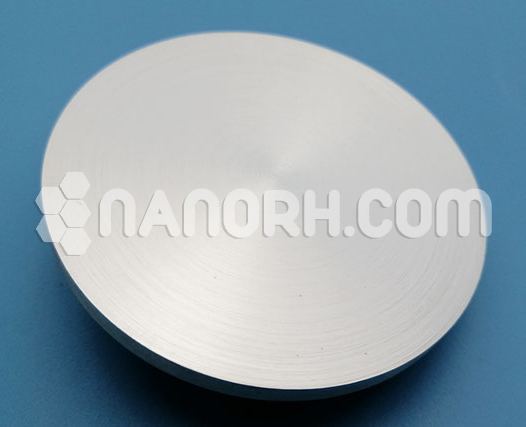

| Copper Zinc Tin Alloy Sputtering Targets | |

| Product No | NRE-43404 |

| CAS No. | NA |

| Formula | CuZnSn |

| Molecular Weight | 247.64 g/mol |

| Purity | >99.9% |

| Density | 8.44-8.78 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Copper Zinc Tin Alloy Sputtering Targets

Copper zinc tin alloy sputtering targets are used in applications where the unique properties of the alloy are advantageous. This alloy, often known for its specific combination of electrical, thermal, and mechanical properties, has diverse applications across various industries.

Transparent Conductive Films

Application: Copper zinc tin alloy (such as Copper Indium Gallium Selenide (CIGS) or other variants) can be used to deposit thin, transparent conductive films for applications in touchscreens, displays, and solar panels.

Benefit: Provides a combination of transparency and electrical conductivity, essential for modern electronic displays and solar energy applications.

Thin-Film Solar Cells

Application: In the production of thin-film solar cells, copper zinc tin alloys can be used as part of the absorber layer or other functional layers.

Benefit: Offers suitable bandgap and absorption characteristics, enhancing the efficiency of solar energy conversion.

Electronics and Semiconductor Devices

Application: Copper zinc tin alloy thin films are used in electronic devices, including semiconductors and interconnects.

Benefit: Provides desirable electrical properties, such as good conductivity and thermal stability, which are crucial for reliable electronic performance.

Optical Coatings

Application: The alloy can be used in optical coatings for devices like mirrors, filters, and lenses.

Benefit: Allows for customization of optical properties such as reflectance and transmission, improving the performance of optical systems.

Wear-Resistant Coatings

Application: Deposited as wear-resistant coatings on mechanical components such as gears, bearings, and shafts.

Benefit: Enhances the durability and longevity of components exposed to friction and mechanical stress.

Thermal Management

Application: Used in thermal management solutions, including heat spreaders and thermal interface materials.

Benefit: Improves heat dissipation from electronic components, aiding in the overall thermal management of devices.

Magnetic Materials

Application: Copper zinc tin alloys can be used in magnetic materials and devices, including magnetic sensors and components.

Benefit: Provides specific magnetic properties depending on the alloy composition, useful for applications requiring precise magnetic characteristics.

Catalysts

Application: The alloy may be employed as a catalyst in various chemical reactions, including industrial processes and environmental applications.

Benefit: Offers catalytic activity that can enhance reaction rates and efficiency.