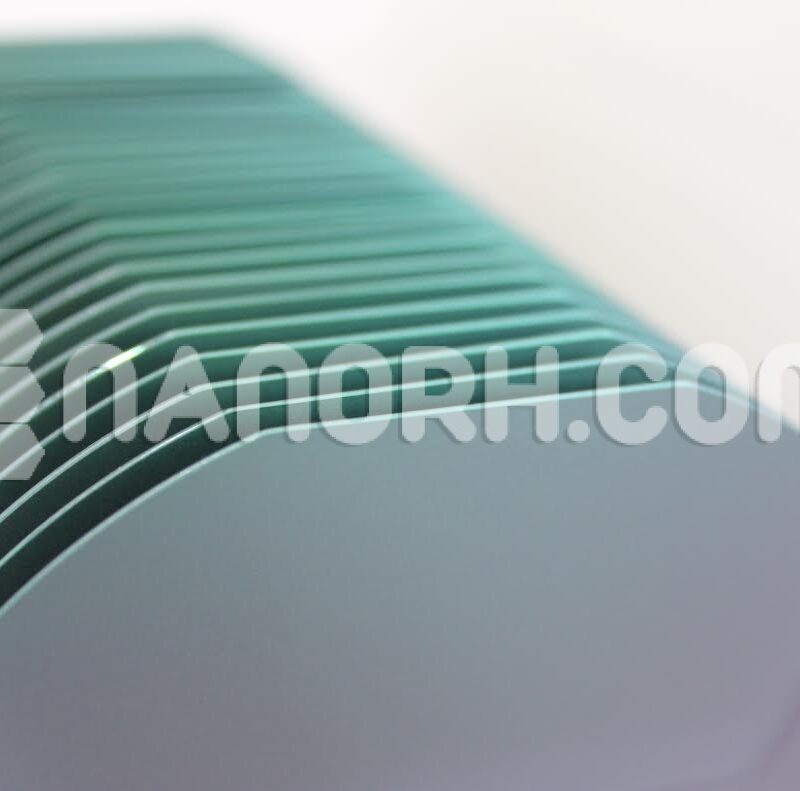

| Copper Sputtering Targets | |

| Product No | NRE-43383 |

| CAS No. | 7440-50-8 |

| Formula | Cu |

| Molecular Weight | 63.55 |

| Purity | >99.9% |

| Density | 8.96 g/cm³ |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Copper Sputtering Targets

Copper sputtering targets are versatile and used in various applications beyond the ones previously mentioned. Here are some additional and specific applications where copper sputtering targets play a crucial role.

Printed Circuit Boards (PCBs)

Application: Copper sputtering is used to deposit conductive layers on PCBs. The thin copper films help in forming the electrical connections between different components on the board.

Benefit: Ensures high conductivity and reliability of electrical signals on the PCB.

Magnetic Sensors and Devices

Application: Copper is used in the fabrication of thin film sensors and magnetic devices, including Hall Effect sensors and inductive sensors.

Benefit: Provides precise and stable magnetic and electrical properties.

MEMS (Micro-Electro-Mechanical Systems)

Application: Copper sputtering is employed in the production of MEMS devices, which are used in a range of applications from automotive sensors to consumer electronics.

Benefit: Contributes to the miniaturization and functionality of MEMS devices through precise deposition of copper layers.

RF (Radio Frequency) Devices

Application: In RF devices, copper sputtering targets are used to deposit conductive layers on substrates that are part of antennas and other RF components.

Benefit: Ensures efficient signal transmission and reception in RF communication systems.

High-Performance Computing (HPC)

Application: Copper sputtering is used to deposit layers in high-performance computing components, including processors and high-speed interconnects.

Benefit: Enhances the performance and speed of computing systems by improving electrical conductivity.

Wear-Resistant Coatings

Application: Copper sputtering targets are used to apply coatings that improve the wear resistance of mechanical components, such as bearings and gears.

Benefit: Extends the lifespan and durability of components subjected to friction and wear.

Battery Technologies

Application: In advanced battery technologies, copper is used in the fabrication of current collectors and other components. Sputtering helps in creating uniform and high-quality copper films.

Benefit: Improves the efficiency and performance of batteries, including lithium-ion batteries.

Electroplating and Surface Finishing

Application: Copper sputtering is sometimes used as a preparatory step before electroplating processes or surface finishing techniques.

Benefit: Provides a uniform and adherent base layer that enhances the quality of subsequent coatings or finishes.