Copper Single Crystal Substrates

Copper Single Crystal Substrates

| Copper Single Crystal Substrates | |

| Product No | NRE-450120-1 |

| CAS | 7440-50-8 |

| Purity | >99.99% (oxygen < 80 ppm) |

| Material | Cu-<100>,/<111>,/<110> |

| Dimensions | 10x10x0.5 |

| Cu Single Substrate Orientation | <100>,/<111>,/<110> |

| Structure | Cubic |

| Thickness | 0.5 mm |

| Polished | Single Side Polished |

| Orientation | +/-2° |

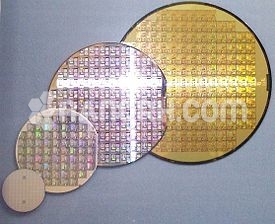

Copper Single Crystal Substrates

Introduction:

Copper single crystal substrates are highly pure and homogenous materials characterized by a uniform crystal structure throughout the substrate. This uniformity offers exceptional electrical and thermal conductivity, making them valuable in various applications within the electronics and materials science fields.

Applications

Electronic Devices:

Cu are used in the fabrication of high-performance electronic devices, including transistors and integrated circuits, where superior electrical conductivity is essential.

Interconnects in Microelectronics:

They serve as interconnect materials in semiconductor devices, providing reliable pathways for electrical signals and enhancing overall device performance.

Thin Film Deposition:

Cu are often used in thin film deposition processes, where their smooth surfaces and consistent crystallographic orientation improve film quality and adhesion.

Photonics and Optoelectronics:

These substrates are employed in optoelectronic applications, such as light-emitting diodes (LEDs) and laser diodes, where high thermal conductivity is required for efficient heat dissipation.

Materials Research:

In materials science, copper single crystal substrates are utilized for fundamental studies of crystallography, electron behavior, and the effects of surface modifications on material properties.

Catalysis:

Due to their high surface area and reactivity, copper single crystal substrates are investigated in catalysis research, particularly for reactions involving gas-solid interactions.

Surface Science Experiments:

They are valuable in surface science studies, allowing researchers to explore phenomena such as adsorption, surface diffusion, and chemical reactions on well-defined surfaces.

MEMS Devices:

Cu can be used in the fabrication of Microelectromechanical Systems (MEMS), where their mechanical properties contribute to device performance.