| Copper Indium Alloy Powder | |

| Product No | NRE-9004 |

| CAS No. | 7440-50-8 / 7440-74-6 |

| Formula | Cu-In |

| Molecular Weight | 178.36 g/mol |

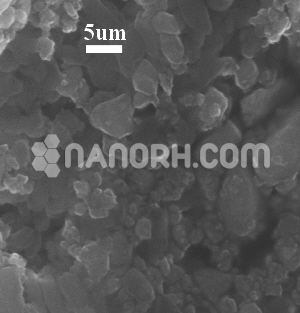

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | NA |

| Color | Gray |

| Melting Point | NA |

| Boiling Point | NA |

Copper Indium Alloy Powder

Applications

Electronics and Semiconductor Industry

Soldering and Bonding Materials: One of the most common applications of CuIn alloys is in the electronics industry, particularly in soldering. CuIn alloys are used in solder materials, especially for creating bonds in semiconductor components due to their low melting point and good thermal conductivity.

Thermal Interface Materials: CuIn alloys are used in applications requiring efficient heat transfer, such as in thermal interface materials (TIMs) for electronics. These materials help to manage heat dissipation in high-performance electronics like microprocessors, LED lighting, and power devices.

Thin-Film Solar Cells

Photovoltaic Industry: CuIn alloys are critical in the production of copper indium gallium selenide (CIGS) thin-film solar cells. These solar cells are highly efficient in converting sunlight into electrical energy, making CuIn alloys essential for renewable energy applications.

The alloy forms the semiconductor material in CIGS cells, where it provides high efficiency and stability under various environmental conditions.

Additive Manufacturing (3D Printing)

Advanced Manufacturing: CuIn alloy powder is used in additive manufacturing technologies like selective laser melting (SLM) or electron beam melting (EBM). Its fine, spherical nature allows for precise control over the deposition of layers during the 3D printing process, making it useful for the fabrication of high-performance parts in electronics, aerospace, and automotive industries.

Electrical Contacts and Components

Conductive Contacts: CuIn alloys are used in the production of electrical contacts, connectors, and components where high conductivity and corrosion resistance are needed. These parts are used in various applications, from consumer electronics to heavy-duty industrial equipment.

Thermal Management Applications

CuIn alloys are effective in thermal management systems due to their good thermal conductivity. They are used in heat exchangers, cooling systems for high-power devices, and components that require efficient heat dissipation, such as power semiconductors and high-performance electrical machinery.