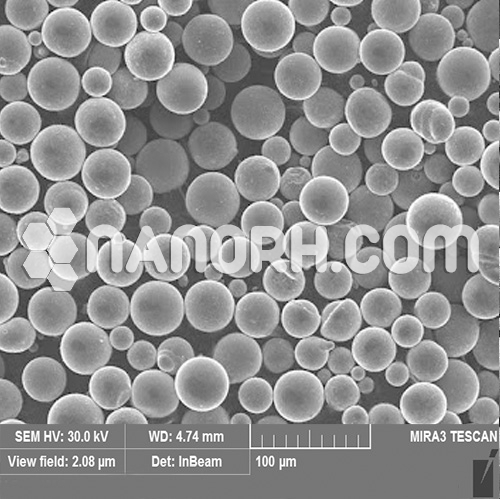

Copper Alloy Powder For 3D Printing

The main application of 3D printing metal powder;

Aerospace

Molds

Automotive

Medical instruments

Military industry

| Product No. | Copper Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60003 | NRE-GCu | Cu>99.5 | <0.15 | 4.8-5.5 | 15-45 µm, 15-53 µm, 20-60 µm, 45-150 µm, D50 10-15 µm |

| NRE-GCuSn10 | Sn 9-11, Cu Bal. | ||||

| NRE-CuNiCrSi | Ni 1.8-3.0,Cr 0.5-0.7,Si 0.4-0.7, Cu Bal. | ||||

| NRE-CuCrZr | Cr 0.5-1.2, Zr 0.02-0.25, Cu Bal. | ||||

| NRE-CuAlNiFe | Al 8.5-11, Ni 4-5.5, Fe 3-5, Cu Bal. | 4.8-5.5 | |||

| NRE-GCuAl | Zn 6-20, Cu Bal. | 4.8-5.5 |

Copper Alloy Powder For 3D Printing

Applications

Electronics Industry:

Heat Sinks and Thermal Management: Copper alloy powder for 3d printing are used in 3D printing of heat sinks, thermal plates, and cooling components for electronic devices, where efficient heat dissipation is critical.

Electrical Connectors and Components: Copper alloy powders are used to create parts like connectors, electrical contacts, and power components, which require excellent electrical conductivity.

RF and Microwave Components: Copper alloys are used in 3D-printed components for radio frequency (RF) and microwave applications due to their high conductivity and low electrical resistance.

Aerospace Industry:

Heat Exchangers: Copper alloys’ excellent thermal conductivity makes them ideal for 3D-printed heat exchangers used in aerospace systems, such as engines or thermal management systems.

Turbine Components: In aerospace, copper alloy powders are used to create parts like turbine blades and engine components that need to manage high temperatures while maintaining performance.

Automotive Industry:

Thermal Management Parts: In the automotive sector, copper alloy powders are used to produce parts like radiators, turbochargers, and cooling systems that require efficient heat transfer and management.

Electrical Components: Copper alloys are also used for automotive electrical parts such as motor windings, connectors, and battery parts due to their superior electrical conductivity.

Medical Industry:

Medical Devices: Copper alloys are used in 3D printing of medical devices and tools, particularly those requiring biocompatibility and strength, such as surgical instruments and implants.

Antimicrobial Surfaces: Due to copper’s natural antimicrobial properties, copper alloys are used for medical components and environments that need to reduce microbial growth, such as hospital door handles, bed rails, and other high-touch surfaces.

Tooling and Manufacturing:

Molds and Dies: Copper alloys are commonly used to 3D-print molds and dies, particularly for injection molding and other industrial applications. The high thermal conductivity of copper allows for better temperature control during the molding process.