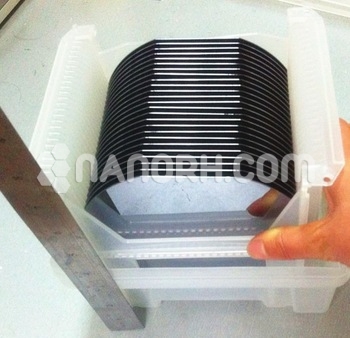

| CoCrW Sputtering Target | |

| Product No | NRE-43036 |

| CAS No. | NA |

| Formula | CoCrW |

| Molecular Weight | NA |

| Purity | 99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

CoCrW Sputtering Target

Cobalt-chromium-tungsten (CoCrW) sputtering targets are used in various specialized applications due to their unique blend of properties, including high hardness, wear resistance, and resistance to corrosion and high temperatures.

Biomedical Applications

Implants and Prosthetics: CoCrW alloys are often used for medical implants, such as hip and knee replacements, dental prosthetics, and other orthopedic devices. The alloy’s biocompatibility, high strength, and resistance to wear and corrosion make it suitable for long-term use in the human body.

Wear-Resistant Coatings

Industrial Tools and Machinery: CoCrW sputtering targets are used to create wear-resistant coatings for cutting tools, bearings, and other industrial components. These coatings enhance the durability and performance of tools by improving their resistance to abrasion and wear.

Aerospace and High-Temperature Applications

High-Performance Coatings: In aerospace and other high-temperature environments, CoCrW coatings are applied to components that must endure extreme conditions. The alloy’s high melting point and oxidation resistance make it ideal for turbine blades, jet engine components, and other critical parts exposed to high temperatures and corrosive environments.

Optical Coatings

Protective and Reflective Coatings: CoCrW thin films can be used in optical coatings to enhance properties such as reflectivity, hardness, and durability. These coatings are applied to optical components like lenses and mirrors to improve their performance and lifespan.

Semiconductor Industry

Barrier Layers and Contacts: In the semiconductor industry, CoCrW alloys are used for depositing thin films that serve as barrier layers or electrical contacts in integrated circuits and other semiconductor devices. The alloy’s stability and conductive properties are beneficial for these applications.

Catalysis

Chemical Reactions: Although less common, CoCrW alloys can be used in catalytic applications where their combination of properties is advantageous. They are employed in industrial processes that require materials with high stability and resistance to harsh conditions.

Electroplating and Electrode Materials

Electroplating Applications: CoCrW sputtering targets are used in electroplating processes to create coatings with specific characteristics. They can also be used in electrode materials for electrochemical processes where durability and resistance to corrosion are required.

Magnetic Materials

Thin Films for Magnetic Applications: CoCrW thin films can be used in magnetic applications where the alloy’s properties provide benefits for certain types of magnetic sensors or data storage technologies.