Cobalt Chromium Alloy Powder

| Cobalt Chromium Alloy Powder | |

| Product Number | NRE-9064 |

| CAS No. | 7440-48-4 / 7440-47-3 |

| Formula | CoCr |

| Molecular Weight | 110.92 g/mol |

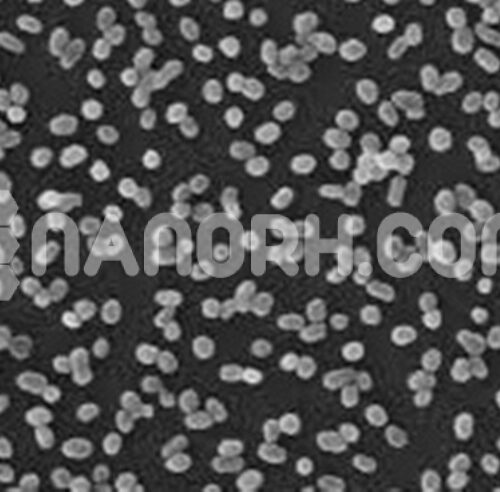

| APS | <40 µm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | 10 g/cm3 |

| Melting Point | 1330 °C |

| Boiling Point | NA |

| Certificate of Analysis | |

| Co | 53.1% |

| Cr | 46.8% |

| Al | 0.02% |

| Fe | 0.04% |

| Cs | 0.02% |

| Mo | 0.02% |

Cobalt Chromium Alloy Powder

Applications

Medical and Dental Implants

Orthopedic Implants: Cobalt chromium alloys are extensively used for producing joint replacements (such as hip and knee implants) due to their biocompatibility, wear resistance, and corrosion resistance. The alloy helps reduce the risk of implant failure and provides long-lasting performance in the human body.

Dental Implants: The corrosion resistance and strength of cobalt chromium make it an ideal material for dental crowns, bridges, dentures, and dental prosthetics. These alloys are resistant to degradation in the mouth’s harsh environment, providing durability and reliability.

Aerospace and Aviation

Turbine Components: Cobalt chromium alloys are widely used for producing turbine blades, compressor blades, nozzles, and other components in jet engines due to their high-temperature strength and corrosion resistance. These parts are subjected to extreme mechanical and thermal stresses, and cobalt chromium’s performance in these conditions ensures durability and efficiency.

Automotive Industry

Turbocharger Components: Cobalt chromium alloy powder is used for manufacturing turbochargers and related components like turbine wheels and compressor wheels. These parts need to withstand high temperatures, stress, and corrosion, and cobalt chromium’s superior properties make it an ideal choice.

Valves and Seats: Engine valves and seats made from cobalt chromium alloys are highly resistant to abrasion, corrosion, and heat, which is essential for maintaining high performance in internal combustion engines.

Brake Discs and Pads: In high-performance automotive applications, cobalt chromium alloys are used for brake discs and pads to enhance wear resistance and heat dissipation during braking.