| Cobalt Aluminate | |

| Product No | NRE-100171 |

| CAS No. | 1333-88-6 |

| Formula | CoAl2O4 |

| Molecular Weight | 176.89 g/mol |

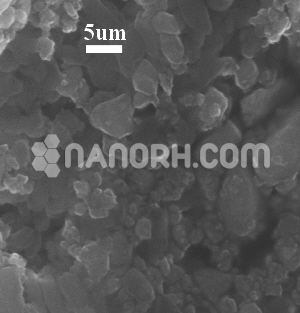

| APS | <2 um(can be customized) |

| Purity | >99% |

| Density | NA |

| Color | Blue |

| Melting Point | NA |

| Boiling Point | NA |

Cobalt Aluminate Applications:

Cobalt aluminate is highly stable, resistant to fading, and insoluble in water, making it suitable for various applications, especially as a pigment. It is a non-toxic and inorganic pigment, which is more stable and durable compared to organic colorants.

Applications

Pigment Industry:

Cobalt Blue Pigment: The most famous application of is as a pigment, commonly known as cobalt blue. It is used extensively in art supplies, oil paints, watercolors, and ceramic glazes. The pigment is favored for its vivid, stable blue color and resistance to fading.

Glazes for Ceramics: is widely used as a colorant in ceramic glazes due to its excellent color properties and heat resistance.

Catalysis:

Catalyst in Chemical Reactions: has been studied and used as a catalyst in certain chemical reactions, such as in the production of hydrogen or methane reforming processes. Its thermal stability and chemical resistance make it a good choice in high-temperature catalytic environments.

Electronics:

Electronics and Superconductor is used in some electronic applications and as a component in superconducting materials. Due to its high-temperature resistance, it is suitable for use in electronic components that need to operate under elevated temperatures or harsh conditions.

Magnetic Materials: In some instances, is used in the production of magnetic materials, where its properties contribute to enhanced performance in certain magnetic applications.

Solar Cells and Energy:

Solar Cell Applications: has been explored as a potential material in solar energy applications, particularly in the development of photovoltaic cells. Its properties make it a potential candidate for use in energy conversion devices.

Coatings and Paints:

Durable Coatings: Due to its color stability, chemical resistance, and thermal stability, is used in industrial coatings and paints that need to withstand harsh conditions, such as high temperatures, UV exposure, and corrosive environments. Examples include coatings for aerospace and automotive industries.