Cobalt Alloy Powder

The main application of 3D printing metal powder;

Aerospace

Molds

Automotive

Medical instruments

Military industry

| Product No. | Cobalt Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| Cobalt Alloy Powder

NRE-60007 |

NRE-CoCrMo | Ni50-55,Cr17-21,Mo2.8-3.3,Nb+Ta4.75-5.5, | 0.1max

0.1max |

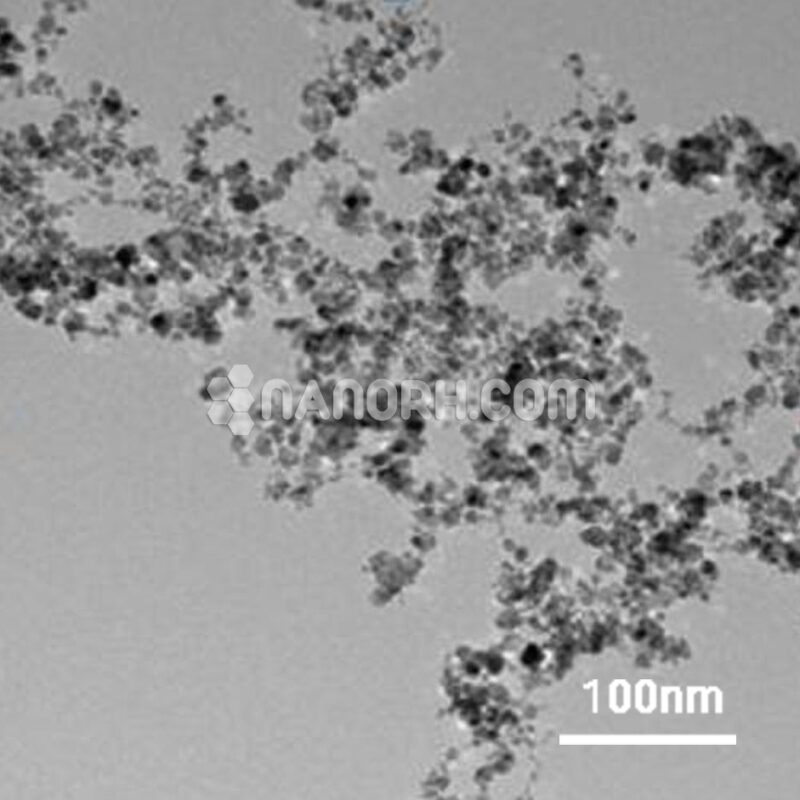

3.8-4.8 | 15-45um,45-150um, D50 1-2um, D50 0.5-1um

0-15um, 15-45um,45-150um |

| NRE-CoCrW | Cr20-23, Mo8-10 |

Cobalt Alloy Powder

Introduction

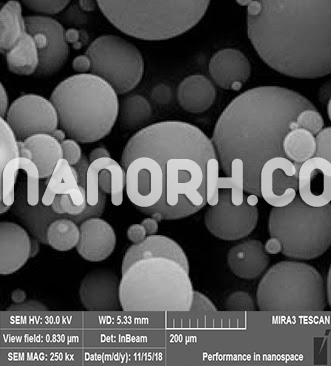

Cobalt alloy powder is a type of material that is produced by alloying cobalt with other metals, such as chromium, nickel, molybdenum, tungsten, and iron. These alloys exhibit exceptional properties like high-temperature resistance, wear resistance, corrosion resistance, and biocompatibility, making them suitable for a wide range of industrial, medical, and technological applications.

Properties

High Temperature Resistance:

Cobalt alloys can withstand extreme temperatures, making them ideal for high-temperature applications such as aerospace engines, turbines, and jet engines. They retain their strength and toughness even under high-heat conditions, which makes them crucial for parts subjected to thermal fatigue.

Wear Resistance:

Cobalt alloys are highly resistant to wear and abrasion. This makes them perfect for applications like cutting tools, drill bits, and machinery components that experience constant friction and wear over time.

Corrosion Resistance:

Many cobalt alloys, especially those combined with elements like chromium or nickel, exhibit excellent corrosion resistance. This makes them ideal for parts exposed to harsh chemicals, moisture, and highly corrosive environments, such as in marine applications or chemical processing plants.

Applications

Aerospace Industry

Cobalt-based superalloys are widely used in aerospace applications due to their high-temperature resistance and strength. Parts such as turbine blades, engine components, exhaust systems, and heat exchangers benefit from the durability and heat resistance of cobalt alloys.

Additive manufacturing using cobalt alloy powders allows for the creation of complex, high-performance aerospace parts that can withstand extreme conditions, including exposure to high thermal stress and erosion.

Medical Industry

In the medical field, cobalt alloys are used to manufacture biocompatible implants, such as hip implants, knee replacements, dental crowns, and prosthetics. Cobalt-chromium alloys are particularly popular because they are durable, corrosion-resistant, and compatible with human tissue, providing long-lasting and safe implants.

3D printing with cobalt alloys enables the creation of customized medical implants, allowing for a better fit to individual patients’ anatomy and reducing recovery times.