| Chromium Carbide Powder | |

| Product No | NRE-5059 |

| CAS No. | 12012-35-0 |

| Formula | Cr3C2 |

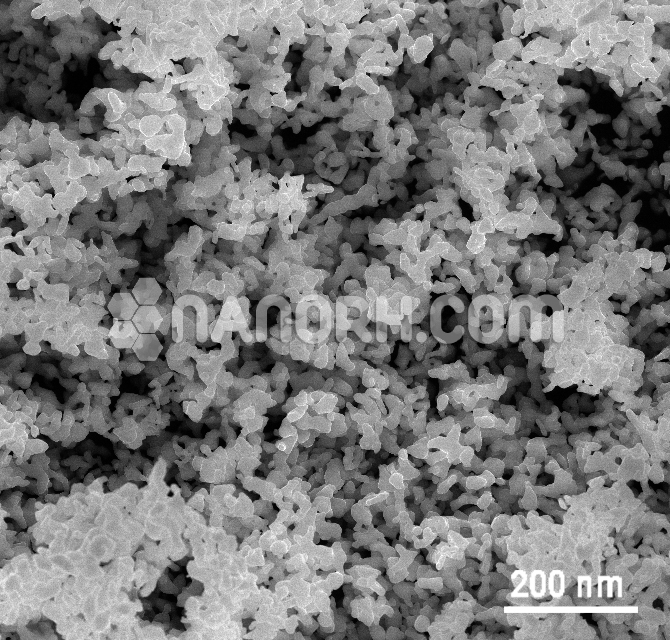

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray-Brown |

| Molecular Weight | 180.0097 g/mol |

| Density | 6.68 g/cm3 |

| Melting Point | 1895°C |

| Boiling Point | 3800°C |

Chromium Carbide Powder

Chromium carbide powder is a refractory ceramic compound composed of chromium and carbon. It is a hard, metallic carbide that exhibits remarkable properties such as high hardness, wear resistance, oxidation resistance, and thermal stability. Chromium carbide powder, available in various particle sizes, is used in a wide range of industrial applications due to these superior properties.

Chromium carbide powder is typically synthesized through processes like chemical vapor deposition (CVD), combustion synthesis, or mechanical alloying.

Applications

Wear-Resistant Coatings:

Chromium carbide powder is widely used to produce wear-resistant coatings on components like machine tools, industrial equipment, and surfaces exposed to abrasion. These coatings can be applied through various techniques such as thermal spraying, electroplating, or high-velocity oxygen fuel (HVOF) spraying. The coatings improve the durability and longevity of the equipment by protecting it from wear and tear.

Cutting Tools and Abrasives:

Due to its hardness, is used in manufacturing cutting tools, drills, and abrasive materials. These tools are essential in industries like mining, construction, and metalworking, where high wear resistance is necessary for cutting, drilling, and grinding.

Thermal Spray Coatings:

In thermal spray processes, is often used to create tough, high-performance coatings that protect industrial equipment from heat and corrosion. These coatings are applied to machinery parts, turbine blades, valves, and other critical components in industries like aerospace, automotive, and energy.

Automotive Components:

Chromium carbide is utilized in automotive parts that require high wear and corrosion resistance, such as brake components, pistons, and engine parts. The powder is used in manufacturing parts that experience heavy friction and high temperatures.

Aerospace Industry:

In aerospace applications, is used to manufacture coatings for turbine blades, nozzles, and other parts exposed to high temperatures and extreme conditions. The powder ensures these components maintain their performance by offering protection against wear, oxidation, and heat.

Mining and Construction:

is used to create wear-resistant materials for mining machinery, such as drill bits, hoppers, and mining tools. These parts are subjected to abrasive conditions, and the chromium carbide coating helps extend their service life.