| Chromium Carbide Nickel Chromium Alloy Powder | |

| Product No | NRE-9002 |

| CAS No. | 12012-35-0/ 7440-02-0 / 7440-47-3 |

| Formula | Cr3C2-NiCr |

| Molecular Weight | 290.699 g/mol |

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | 2.3 g/cm3 |

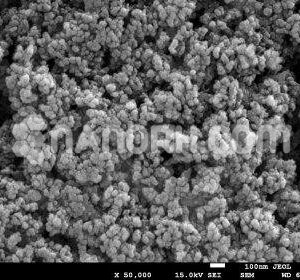

| Color | Gray |

| Melting Point | NA |

| Boiling Point | NA |

Chromium Carbide Nickel Chromium Alloy Powder

Applications

Wear-Resistant Coatings and Linings

Mining and Cement Industry: Chromium carbide is commonly used in the mining, cement, and other heavy industries for producing wear-resistant coatings on parts such as crusher liners, grinding mills, and chutes. The abrasion resistance and toughness of the alloy make it ideal for high-wear components exposed to hard materials and extreme conditions.

Aerospace and Aviation

Engine Components: Chromium carbide nickel chromium alloy powder is used in aerospace for producing high-performance engine parts such as turbine blades, nozzles, and fuel injectors. These components require high-temperature stability, wear resistance, and corrosion resistance to perform in harsh environments.

Exhaust Systems: The alloy is also used in exhaust systems and heat exchangers where components experience both high temperatures and aggressive atmospheric conditions.

Automotive Industry

Turbocharger Components: Turbochargers in high-performance automotive engines require materials that can withstand extreme temperatures and high-speed rotations. The wear resistance and thermal stability of chromium carbide nickel chromium alloy make it suitable for compressor wheels and turbine blades.

Engine Valves and Seats: Parts such as engine valves and seats that experience heavy wear from friction, heat, and chemical exposure benefit from the high hardness and corrosion resistance of this alloy.

Marine Industry

Propellers and Rudders: The corrosion resistance and wear resistance of chromium carbide nickel chromium alloy make it ideal for use in marine environments, where components are exposed to saltwater and heavy physical stresses. This alloy is used for making propellers, rudders, and boat hulls.

Oil and Gas Industry

Drilling Equipment: In the oil and gas sector, chromium carbide nickel chromium alloy powder is used for creating durable parts like drill bits, cutting tools, and tubing that must endure extreme wear, high pressure, and chemical exposure.