|

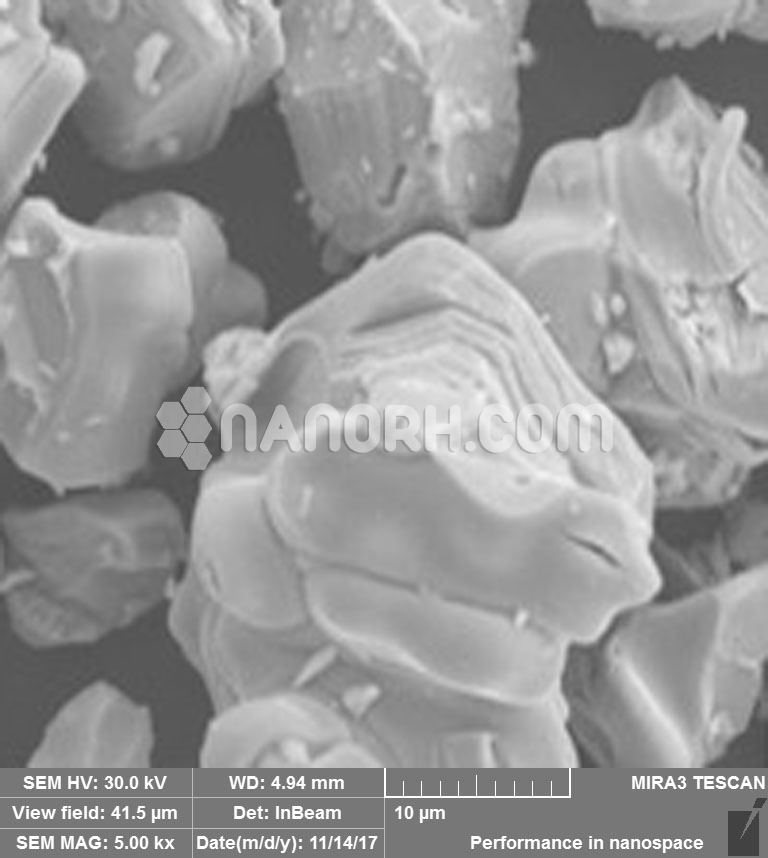

Chromium Aluminum Carbide MAX Phase Powder |

|

| Product No. | NRE-58001 |

| CAS No. | 12179-41-8 |

| Formula | Cr2AlC |

| Molecular Weight | 142.98 g/mol |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

|

Certificate of Analysis |

|

| Al | 18.8% |

| Cr | 72.7% |

| C | 8.4% |

| O | 0.02% |

| B | 0.04% |

| Cu | 0.03% |

| Sn | 0.01% |

Chromium Aluminum Carbide MAX Phase Powder

Chromium Aluminium Carbide MAX phase powder is a member of the MAX phase family of materials. These materials are known for their unique combination of metallic and ceramic properties, making them highly versatile and valuable for various advanced applications. The general formula for MAX phases is Mn_nnAXn−1_{n-1}n−1, where M is an early transition metal (in this case, chromium), A is an A-group element (aluminium), and X is carbon.

Properties and Characteristics

Mechanical Strength: These materials have high strength and hardness, attributed to their ceramic components, while retaining the damage tolerance of metals.

Oxidation Resistance: Cr-Al-C MAX phases are known for their outstanding oxidation resistance, making them suitable for applications in oxidative environments.

Electrical Conductivity: Unlike traditional ceramics, Cr-Al-C Chromium Aluminium Carbide MAX phase powder are good electrical conductors, which is beneficial for various electronic and electrical applications.

Ductility: They exhibit good ductility and can deform plastically at high temperatures, which is uncommon for most ceramics.

Synthesis and Processing

Raw Material Selection: High-purity chromium, aluminium, and carbon sources are selected as starting materials.

Mixing and Milling: The raw materials are mixed in the appropriate stoichiometric ratio and often subjected to ball milling to ensure a uniform mixture.

High-Temperature Sintering: The mixed powder is then sintered at high temperatures (usually above 1200°C) in an inert or reducing atmosphere. This step facilitates the formation of the MAX phase structure.

Post-Synthesis Treatment: The sintered material may undergo additional treatments, such as annealing or hot pressing, to enhance its structural and phase purity.

Applications

Aerospace: Due to their high-temperature stability and oxidation resistance, Cr-Al-C Chromium Aluminium Carbide MAX Phase Powder are used in aerospace components like turbine blades, where they can withstand extreme conditions

Electronics: Their electrical conductivity and thermal stability make these materials suitable for electronic applications, including thermal management systems and conductive components

Energy: Cr-Al-C Chromium Aluminium Carbide MAX phase powder are explored for use in nuclear reactors and other energy-related applications due to their ability to endure high temperatures and radiation environments.