| AZ91D alloy powder | |

| Product No | NRE-60102 |

| Purity | 99.9% |

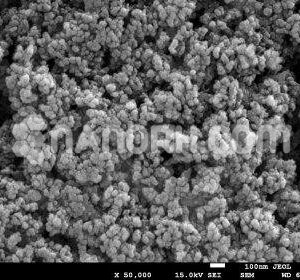

| Mesh | 15-53 mesh |

| Color | Silver Gray |

| AZ91D | |||||||||

| Composition | Mg | Al | Cu | Fe | Mn | Ni | Si | Zn | Be |

| wt% | 90.43 | 8.90 | 0.0006 | 0. 0112 | 0.19 | 0.003 | 0.003 | 0.4278 | 0.00098 |

AZ91D alloy powder

Introduction

AZ91D alloy powder is one of the most widely used magnesium alloys, containing approximately 9% aluminum (Al) and 1% zinc (Zn) by weight, with small amounts of manganese (Mn) and silicon (Si). AZ91D is known for its good castability, high strength-to-weight ratio, corrosion resistance, and excellent machinability. It is particularly favored in applications where light weight, durability, and cost-effectiveness are important, making it an ideal choice for automotive, aerospace, and other high-performance industries.

Key Features

Lightweight:

Magnesium alloys, including AZ91D, are known for their low density (about 1.8 g/cm³), which makes them suitable for applications where weight reduction is a priority, such as in the aerospace and automotive sectors.

High Strength-to-Weight Ratio:

AZ91D offers excellent mechanical properties, including good tensile strength and fatigue resistance, making it ideal for lightweight, high-strength applications.

Corrosion Resistance:

AZ91D has good resistance to corrosion, especially in environments with low humidity and in non-aggressive chemicals. Its resistance can be further enhanced through coatings and alloying elements like aluminum and zinc.

Good Castability:

AZ91D is highly castable, meaning it can be poured into molds with good results, making it ideal for die-casting and other casting processes. The alloy’s good flow characteristics in the molten state ensure high-quality castings.

Improved Machinability:

This alloy has excellent machinability compared to other magnesium alloys, allowing for high-precision manufacturing of complex parts with minimal tool wear.

Thermal Conductivity and Damping Properties:

Magnesium alloys like AZ91D have high thermal conductivity and good vibration damping, which are beneficial in applications that require effective heat dissipation and noise reduction.

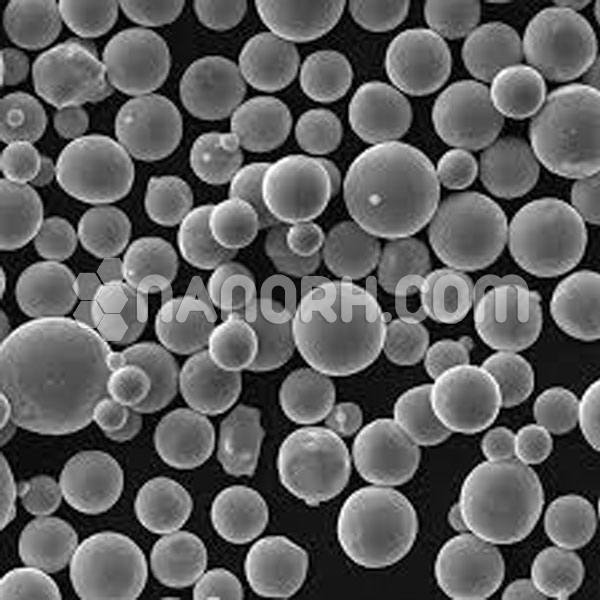

Spherical Powder Shape:

The atomization process creates spherical powder particles, improving flowability and making the material well-suited for additive manufacturing (3D printing), powder metallurgy, and other advanced manufacturing methods.