| Atomized spherical Mg-Zn alloy powder | |

| Product No | NRE-60101 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Product | Ratio Mg: Zn | Real density(g/cm³) | Calorific value(J/g) |

|

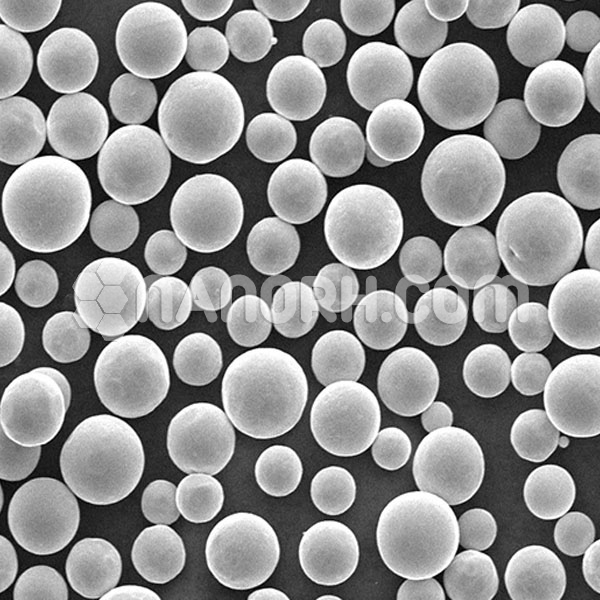

Atomized spherical Mg-Zn alloy powder |

70:30 | 2.26 | 18110 |

| 30:70 | 3.47 | 11180 | |

| 50:50 | 2.83 | 15050 | |

| 20:80 | 4.23 | 9240 | |

| 10:90 | 5.25 | 7300 | |

| 90:10 | 1.92 | 24110 | |

| 95:5 | 1.82 | 24136 |

Atomized spherical Mg-Zn alloy powder

Magnesium alloy is widely used in portable equipment and the automotive industry to achieve the goal of being lightweight.

Mg-Zn alloy atomized powder changed the melting point of zinc powder and the starting point of intense oxidation, completely solved the problems of ignition and stable combustion and is expected to be widely used in pyrotechnics and in other fields.

Applications:

Aerospace: Lightweight structural components such as brackets, engine components, and heat exchangers.

Automotive: High-performance parts like engine components, transmission components, and body panels.

Medical: Custom implants, prosthetics, and medical device prototypes where lightweight and biocompatibility are crucial.

Features: Mg-Zn alloy powders are ideal for 3D printing due to their excellent flowability and ability to produce parts with complex geometries and high mechanical strength, reducing material waste and offering design flexibility.

Powder Metallurgy (PM):

Applications:

Automotive: Structural components, gears, bearings, and lightweight parts for enhanced fuel efficiency.

Aerospace: High-strength parts such as structural brackets, components exposed to mechanical stress, and housings for sensitive equipment.

Advantages: The use of Mg-Zn alloy powders in powder metallurgy allows for the production of high-strength, lightweight parts with precise geometries and minimal porosity, making them ideal for demanding applications in the aerospace and automotive industries.

Thermal Spray Coatings:

Applications:

Corrosion protection for components exposed to harsh environments, such as marine or industrial machinery parts.

Wear resistance coatings for tools, aerospace components, and automotive parts.

Process: Thermal spraying methods such as plasma spraying or flame spraying can be used to apply Mg-Zn alloy coatings, which offer corrosion resistance and wear protection to underlying materials.

Advantages: The coatings improve the durability of components, especially in environments where exposure to high temperatures and corrosive elements is common.

Casting and Die-Casting:

Applications:

Automotive: Magnesium alloy die-cast parts for automotive engines, transmissions, and lightweight structural components.