| Atomized spherical magnesium powder | |

| Product No | NRE-60104 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Commodity name | Atomized spherical magnesium powder |

| Manufacturing method | centrifugal atomization |

| Appearance | silver grey spherical powder |

| PSD | 20-500mesh |

| Purity | 99.9%min |

| Package | 0.5-5kg/bag or 50-200kg/drum |

| Shape | spherical | |

| Proportion of Sphere /% | ≥95 | |

| Apparent density/g·cm-3 | 0.90(min) | |

| Real density/g·cm-3 | 1.73 | |

| Fluidity/s·(50g)-1 | 78.6 | |

| Moisture absorption rate /% | 0.01 | |

| Active Mg content /% | 99.0(min) | |

| Calorific value/kJ/g | 26.09 | |

| Calorific density/kJ/cm3 | 45.39 | |

|

Impurity

content

/% |

Moisture/%(max) | 0.05 |

| Insoluble material in HCl /%(max) | 0.13 | |

| Oil & grease/%(max) | 0.00 | |

| Fe/%(max) | 0.01 | |

| Mn/%(max) | 0.008 | |

| Zn/%(max) | 0.008 | |

| Cl/%(max) | 0.003 | |

Atomized spherical magnesium powder

Introduction:

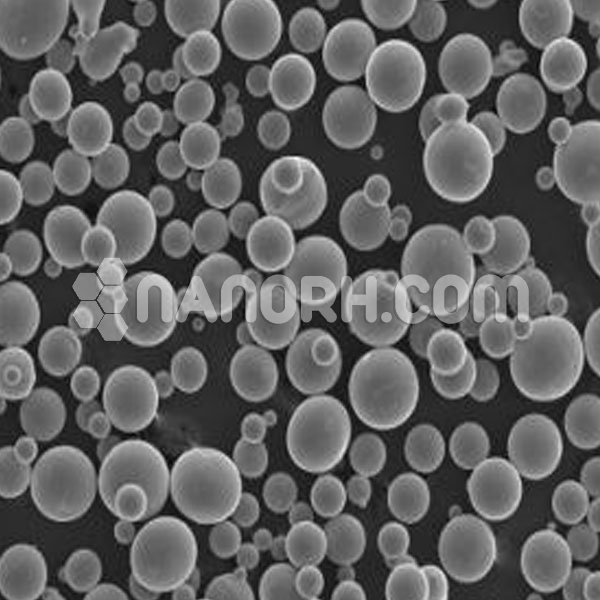

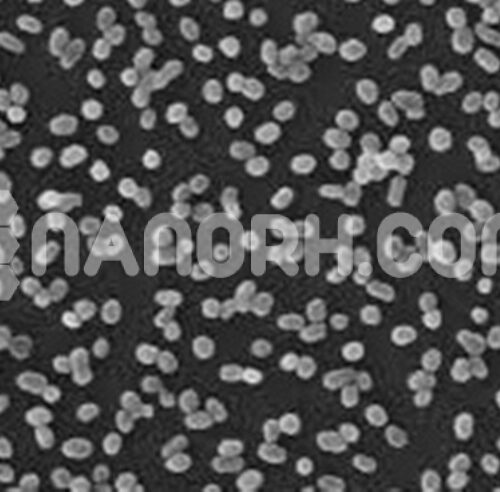

Atomized spherical magnesium powder refers to magnesium (Mg) particles that have been produced using an atomization process, which involves breaking down molten magnesium into small droplets that solidify into spherical shapes as they cool. This powder has a highly uniform particle size distribution and is often used in a variety of industrial, chemical, and manufacturing applications.

Magnesium, being a light metal with a density about two-thirds that of aluminum, is highly valued for its strength-to-weight ratio. It is also the lightest structural metal, which makes it ideal for applications requiring lightweight materials. However, magnesium is highly reactive and can be difficult to handle in its bulk form, which is why atomization into a fine powder allows for more controlled applications.

Atomization is typically performed through methods like gas atomization or water atomization, where molten magnesium is forced through a nozzle and rapidly cooled to form powder. The spherical shape of the powder particles enhances their flowability, which is a significant advantage in various applications.

Properties

Uniform Particle Size: The atomization process creates a consistent particle size distribution, which makes the powder suitable for applications that require precise control over material properties.

Spherical Shape: The spherical shape of the powder particles ensures good flowability, which is important for processes such as powder metallurgy, additive manufacturing, and compaction.

High Reactivity: Magnesium is highly reactive, especially when in powder form. This property makes magnesium powder valuable in specific chemical reactions and industrial processes.