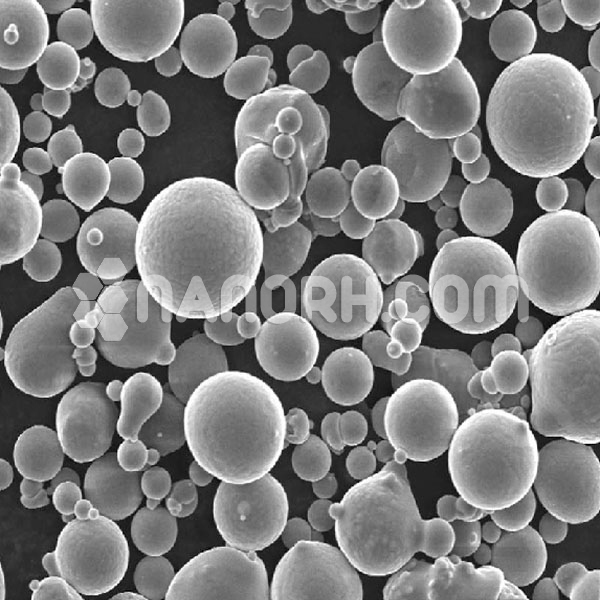

| Atomized spherical Aluminum based alloy powder | |

| Product No | NRE-60100 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

AlZn8020

|

Composition |

wt. (%) | |||||||

| Zn | Fe | Si | Cu | Ti | Mg | Mn | Al | |

| 19.055% | 0.095% | 0.033% | 0.01% | 0.005% | 0.01% | 0.02% | balance | |

AlZn9010

|

Composition |

wt. (%) | |||||||

| Zn | Fe | Si | Cu | Ti | Mg | Mn | Al | |

| 0.095% | 0.095% | 0.033% | 0.01% | 0.005% | 0.01% | 0.02% | balance | |

Theoretical density and combustion heat

| Sample

(g/cm³) |

Theoretical density

(g/cm³) |

Combustion Heatk

(J/g) |

Calculated value according to alloy ratio (J/g) |

| Al-Zn9010-6μm | 2.87 | 26.61 | 26.76 |

| Al-Zn8020-6μm | 3.08 | 23.42 | 24.38 |

Atomized spherical Aluminum based alloy powder

Applications of Atomized Spherical Aluminum-Based Alloy Powders:

Additive Manufacturing (3D Printing):

Process: Selective Laser Melting (SLM), Electron Beam Melting (EBM), Direct Energy Deposition (DED)

Applications:

Production of lightweight, complex parts with minimal material waste.

Aerospace (engine components, brackets, heat exchangers), automotive (engine blocks, lightweight chassis), medical (implants, prosthetics).

Features: The powders’ excellent flowability and consistent particle size make them ideal for high-precision 3D printing.

Powder Metallurgy (PM):

Process: Sintering

Applications:

Gears, bearings, automotive components (brackets, structural parts).

Advantages: Atomized spherical powders enable better densification, improved mechanical properties, and reduced porosity in final parts.

Thermal Spray Coatings:

Process: Plasma spraying, flame spraying, HVOF (High-Velocity Oxygen Fuel)

Applications:

Protective coatings on parts exposed to high temperatures and wear, such as turbine blades, heat exchangers, and marine components.

Features: Aluminum-based coatings offer corrosion resistance, wear resistance, and thermal protection.

Metal Injection Molding (MIM):

Process: Powder mixed with binder, then injected into molds and sintered.

Applications:

Complex, small parts like connectors, brackets, and internal components.

Advantages: Ideal for producing high-density parts with intricate designs and minimal material waste.

Casting and Die-Casting:

Process: Use of powders in die-casting or compaction processes.

Applications:

Automotive engine parts, structural components, and housings.

Features: The use of atomized powders improves the mechanical properties of cast parts, reducing defects like porosity and improving overall strength.

Powder Coating:

Process: Electrostatic spraying followed by curing.

Applications:

Coatings for automotive parts (bumpers, wheels), appliances, and architectural elements (window frames).