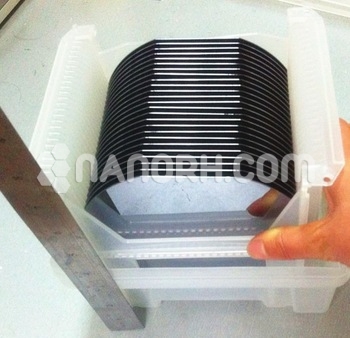

| Aluminum Nickel Alloy Sputtering Targets | |

| Product No | NRE-43313 |

| CAS No. | 12635-27-7 |

| Formula | Al-Ni |

| Molecular Weight | 85.674g/mol |

| Purity | >99.9% |

| Density | 7.5 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Aluminum Nickel Alloy Sputtering Targets

Aluminum nickel (Al-Ni) alloy sputtering targets are used to deposit thin films with specific properties that make them suitable for a variety of high-tech applications. The combination of aluminum and nickel imparts unique attributes to the sputtered films, benefiting several industries. Here’s a detailed look at the applications of Al-Ni sputtering targets:

Applications of Aluminum Nickel Alloy Sputtering Targets

Magnetic Thin Films:

Magnetic Recording Media: Al-Ni thin films are used in the production of magnetic recording media, including hard drives and other data storage devices. The nickel content enhances the magnetic properties, which is important for high-density data storage.

Magnetic Sensors: These films are utilized in magnetic sensors and devices, where precise magnetic properties are needed for applications such as automotive sensors, industrial measurements, and consumer electronics.

Electronic Components:

Conductive Films: Al-Ni films are employed in various electronic components as conductive layers. The alloy’s combination of aluminum and nickel provides good electrical conductivity and stability, which is useful in devices like thin-film transistors (TFTs) and integrated circuits.

Interconnects and Contacts: The alloy can be used for creating interconnects and contact layers in semiconductor devices, improving reliability and performance.

Optical Coatings:

Reflective Coatings: Al-Ni thin films can be used as reflective coatings in optical systems. The alloy’s optical properties can be tailored to enhance reflectivity for applications in mirrors, lenses, and optical filters.

Anti-Reflective Coatings: These films may also be applied in anti-reflective coatings to reduce glare and enhance light transmission in optical devices.

Protective Coatings:

Corrosion Resistance: Al-Ni coatings can improve the corrosion resistance of various substrates, making them suitable for use in environments where protection from oxidation and chemical degradation is necessary.

Wear Resistance: The alloy’s properties can enhance the wear resistance of coated surfaces, which is beneficial for applications involving mechanical stress and abrasion.

Catalysts and Chemical Processes:

Catalytic Coatings: Al-Ni films can serve as catalytic coatings in certain chemical reactions. The alloy’s properties can enhance catalytic activity and stability, which is useful in industrial processes and chemical reactors.

Battery Technology:

Electrode Materials: Al-Ni alloys can be used in battery technologies, especially in rechargeable batteries where improved conductivity and stability are required. The alloy can enhance the performance and lifespan of battery electrodes.