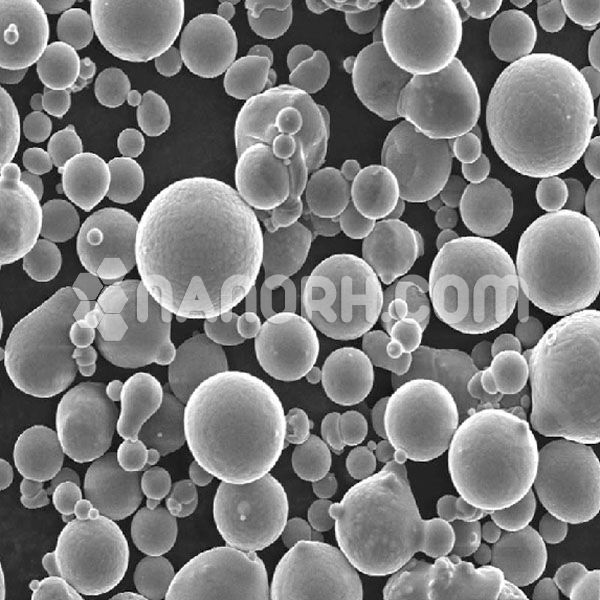

| Aluminum based alloy Spherical powder | |

| Product No | NRE-60100 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

AlZn8020

|

Composition |

wt. (%) | |||||||

| Zn | Fe | Si | Cu | Ti | Mg | Mn | Al | |

| 19.055% | 0.095% | 0.033% | 0.01% | 0.005% | 0.01% | 0.02% | balance | |

AlZn9010

|

Composition |

wt. (%) | |||||||

| Zn | Fe | Si | Cu | Ti | Mg | Mn | Al | |

| 0.095% | 0.095% | 0.033% | 0.01% | 0.005% | 0.01% | 0.02% | balance | |

Theoretical density and combustion heat

| Sample

(g/cm³) |

Theoretical density

(g/cm³) |

Combustion Heatk

(J/g) |

Calculated value according to alloy ratio (J/g) |

| Al-Zn9010-6μm | 2.87 | 26.61 | 26.76 |

| Al-Zn8020-6μm | 3.08 | 23.42 | 24.38 |

Aluminum based alloy Spherical powder

Additive Manufacturing (3D Printing)

Applications:

Selective Laser Melting (SLM), Selective Laser Sintering (SLS), and Electron Beam Melting (EBM) are widely used to process aluminum-based alloy spherical powders. These processes are particularly popular in aerospace, automotive, and medical industries for producing complex parts with minimal material waste.

Common Alloys: AlSi10Mg, AlSi7Mg0.6, Al-6061, and other aluminum alloys are typically used in 3D printing for producing lightweight, durable, and high-performance parts.

Powder Metallurgy

Applications:

Sintering Process: Aluminum alloy powders are often used in powder metallurgy (PM) processes to create parts with high density and precision. The spherical shape enhances powder flowability and reduces defects during sintering.

Typical Products: Gears, bearings, bushings, automotive components, and other structural parts.

Advantages: The use of aluminum alloys helps reduce weight, maintain strength, and improve wear resistance in metal parts.

Thermal Spray Coatings

Applications:

Aluminum-based alloy powders are used for thermal spray processes (such as plasma spraying, flame spraying, or HVOF) to deposit protective coatings on substrates.

These coatings are particularly useful in high-temperature applications, such as aerospace, marine, and industrial equipment, where corrosion resistance, wear resistance, and thermal protection are needed.

Metal Injection Molding (MIM)

Applications:

MIM uses aluminum alloy powders mixed with a binder to produce complex shapes in high volumes. The powder is injected into molds and then sintered to achieve full density and mechanical strength.

Applications: Small to medium-sized parts, such as connectors, brackets, and internal components in industries like automotive, electronics, and consumer goods.

Casting and Die-Casting

Applications:

Aluminum alloy powders are used in the casting and die-casting industries to improve the quality of cast parts, offering enhanced material properties such as improved fatigue strength and corrosion resistance.

Powder for Compaction: Used in producing complex geometries in casting processes, where traditional methods may be difficult or costly.

Applications: Automotive components (engine blocks, transmission parts), aerospace components, and electrical housings.