Aluminium Silicon Magnesium Alloy Spherical Powder

Aluminium Silicon Magnesium Alloy Spherical Powder

| Aluminium Silicon Magnesium Alloy Spherical Powder | |

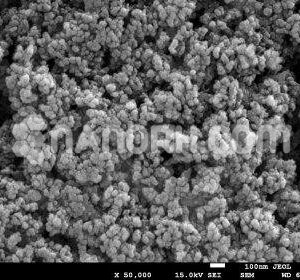

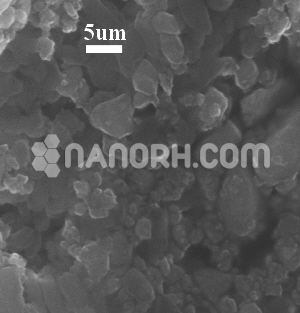

| Product No | NRE-9062 |

| CAS | NA |

| Purity | 99.9% |

| Formula | AlSiMg |

| APS | <40um (can be customized) |

| Color | NA |

| Molecular Weight | 79.372038 g/mol |

| Density | 1.8 g/cm3 |

| Melting Point | NA |

| Boiling Point | NA |

Aluminium Silicon Magnesium Alloy Spherical Powder

Applications

Aerospace Industry

The aerospace industry benefits from the high strength, lightweight, and corrosion-resistant properties of this alloy:

Aircraft Components: The alloy is used for producing lightweight structural components such as wing spars, brackets, and fuselage parts that need to withstand high mechanical stresses without adding excessive weight.

Engine Parts: Critical components like turbine blades, engine casings, and mounting brackets can be made from Al-Si-Mg alloy powder to ensure high thermal stability and wear resistance in high-performance environments.

Automotive Industry

In the automotive industry, Aluminium Silicon Magnesium alloys are commonly used for parts that require strength, lightweight, and durability:

Engine Components: Parts such as engine blocks, cylinder heads, and pistons benefit from the alloy’s high strength-to-weight ratio, thermal stability, and wear resistance, making them suitable for high-performance engines.

Transmission Parts: Gears, shafts, and clutch housings are often 3D printed with Al-Si-Mg alloy powder, as these components need to withstand constant friction while maintaining low weight for improved vehicle efficiency.

Marine Industry

The marine industry is another sector that benefits from the corrosion resistance and lightweight properties of the Al-Si-Mg alloy:

Boat Hulls and Structural Parts: Components such as hulls, rudders, and propellers made from Al-Si-Mg alloy powder are resistant to saltwater corrosion, which is essential in marine environments where parts are exposed to harsh conditions.

Marine Engine Parts: Marine engine blocks, pumps, and valves can be made with Al-Si-Mg alloy powder, providing durability and resistance to corrosion and wear under harsh conditions.

Machinery Parts: Bearings, gearboxes, and shafts benefit from the alloy’s high wear resistance and strength, ensuring that they can withstand heavy-duty use.

Casting Molds: Al-Si-Mg alloy powder is also used for 3D printing casting molds that require high thermal stability, wear resistance, and excellent fluidity during casting processes.