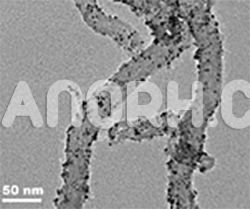

Copper coated Carbon Nanotubes (Cu/CNT)

| Copper coated Carbon Nanotubes | |

| Product No | NRE-42001 |

| CAS No. | 7440-50-8/308068-56-6 |

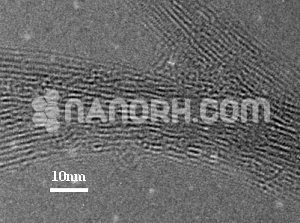

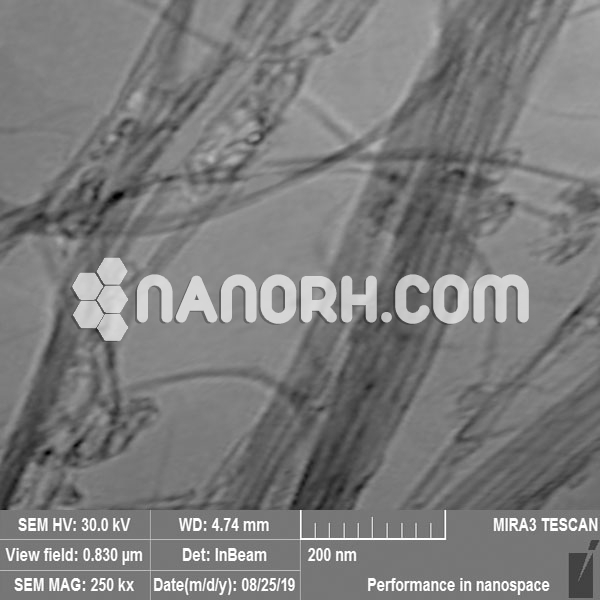

| Outer Diameter | 35-50 nm |

| Inner Diameter | 5-25nm |

| Average Length | 10-20um |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | > 100 S/cm |

| Metal Percentage | 2-5% (can be Customized) |

Copper coated Carbon Nanotubes – exhibit outstanding chemical activity due to their large active surface area and unique crystallographic surface structure.

CNTs decorated with metal nanoparticles (NPs) like Silver nanoparticles, Gold nanoparticles, Nickel nanoparticles, copper nanoparticles, Magnesium nanoparticles, palladium nanoparticles, platinum nanoparticles, exhibit outstanding chemical activity due to their large active surface area and unique crystallographic surface structure.

Applications

Electronics and Nanoelectronics

Conductive Materials: Cu-CNTs are used in the manufacture of highly conductive inks for printed electronics, flexible circuits, and conductive adhesives. Their high conductivity makes them ideal for flexible displays, touchscreens, and other electronic devices.

Interconnects in Microelectronics: Copper is a key material used for interconnections in semiconductor devices. By coating CNTs with copper, it is possible to create ultra-fine, high-performance interconnects that reduce resistance and improve device performance at the nanoscale.

Electromagnetic Shielding: Cu-CNTs can be used to create materials for electromagnetic interference (EMI) shielding. Their conductive nature helps block unwanted electromagnetic signals.

Energy Storage and Conversion

Supercapacitors and Batteries: Cu-CNTs are being explored as electrodes in energy storage devices, including supercapacitors and batteries. The copper coating enhances electrical conductivity, while the CNTs provide a high surface area and excellent charge/discharge rates, improving the overall performance and efficiency of the devices.

Hydrogen Storage: The high surface area and conductivity of Cu-CNTs make them potential candidates for hydrogen storage applications, where hydrogen molecules can be adsorbed on the surface of CNTs for fuel cell applications.

Thermal Management

Heat Sinks and Thermal Conductive Materials: Due to their excellent thermal conductivity, Cu-CNTs are used in heat management systems, such as heat sinks for electronic devices, LED cooling, and other applications requiring efficient heat dissipation.

Thermal Interface Materials: Cu-CNT composites are utilized in advanced thermal interface materials (TIMs) that improve heat transfer between electronic components (e.g., processors) and cooling systems.

Materials and Structural Composites

Reinforced Polymers and Composites: Cu-CNTs can be used as fillers in polymer composites to improve their mechanical properties and electrical conductivity. These composites are used in a range of industries, including automotive, aerospace, and manufacturing, where lightweight, strong, and conductive materials are needed.

Conductive Coatings: Cu-CNTs are used in conductive coatings for various applications, including the production of conductive textiles, automotive coatings, and coatings for solar panels.