| Silicon Oxide/ Gold core-shell Nanoparticles | |

| Product No | NRE-16075 |

| CAS No. | 7631-86-9/7440-57-5 |

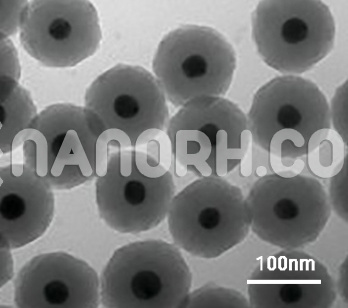

| Formula | SiO2/Au |

| APS | <100nm (can be customized) |

| Shape | Spherical |

| Purity | 99.9% |

| Core | Silicon Oxide |

| Shell | Gold |

| Appearance | Powder |

| Boiling Point | NA |

Silicon Oxide/ Gold core-shell Nanoparticles

Silicon oxide/ gold core-shell nanoparticles are two materials with widely recognized and complementary properties in the fields of nanotechnology, materials science, and biomedical engineering. When combined in a core-shell structure, with silicon oxide as the core and gold as the shell, these nanoparticles exhibit enhanced characteristics that make them suitable for a wide variety of applications, especially in areas requiring both high surface functionality and biocompatibility.

Applications

Composites and Coatings:

Enhanced Mechanical Properties: The silica core provides rigidity and strength, while the rubber shell adds flexibility and toughness. This combination makes silica latex rubber core-shell nanoparticles ideal for reinforcing composite materials used in coatings, adhesives, and sealants. They help improve the impact resistance, abrasion resistance, and durability of the composite materials.

Rubber Coatings: In industrial coatings, these nanoparticles are used to enhance the mechanical properties (such as elasticity, flexibility, and tensile strength) of rubber-based coatings, which are often applied to automotive parts, pipes, and protective films. The silica core also helps in improving the adhesion of the coating to various substrates.

Rubber Industry:

Improved Rubber Performance: In the rubber manufacturing industry, silica latex rubber core-shell nanoparticles are used as fillers or reinforcers in rubber formulations, such as those used in tires, conveyor belts, and gaskets. The addition of silica to rubber improves its mechanical properties (such as tear resistance and tensile strength) while maintaining or even enhancing its elasticity due to the rubber shell.

Tire Manufacturing: One of the most notable applications is in tire production, where these core-shell nanoparticles are used to enhance the performance of rubber compounds. Silica-filled rubber composites improve the rolling resistance, durability, and wet traction properties of tires, leading to better fuel efficiency and performance in vehicles.

Biomedical and Drug Delivery:

Drug Delivery Systems: The combination of silica and rubber in core-shell nanoparticles is promising for drug delivery applications. The silica core can be functionalized to carry drugs or therapeutic agents, while the rubber shell provides a controlled release mechanism and protects the encapsulated drug from degradation. The flexibility of the rubber shell makes these nanoparticles suitable for targeted drug delivery, particularly in applications that require deformation, such as crossing biological barriers or encapsulating biologically active molecules.

Biocompatibility: The silica core is often biocompatible, making these nanoparticles suitable for biomedical applications. They are used in controlled-release drug delivery systems, imaging, and as carriers for diagnostic agents.

Electronics and Conductive Materials:

Flexible Electronics: Silica latex rubber core-shell nanoparticles are increasingly being used in flexible electronics and wearable devices due to their combination of electrical conductivity and mechanical flexibility.