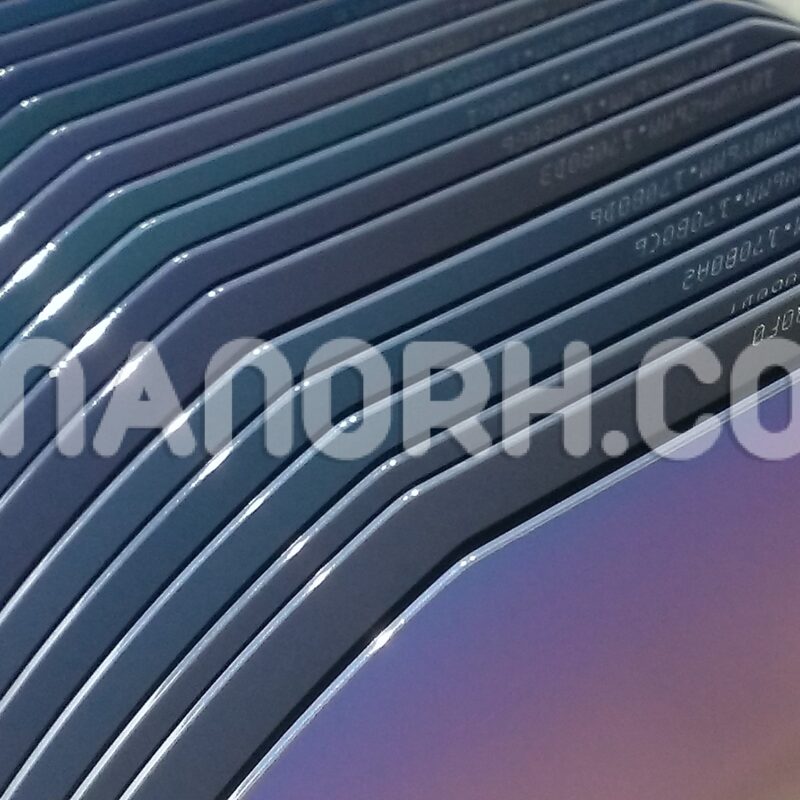

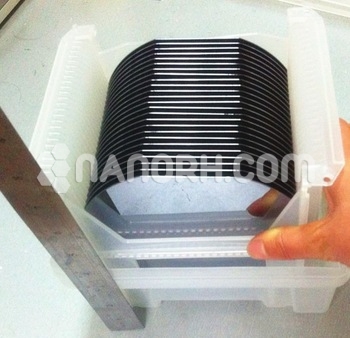

| Boron Sputtering Target | |

| Product No | NRE-43021 |

| CAS No. | 7440-42-8 |

| Formula | B |

| Molecular Weight | 10.81 g/mol |

| Purity | >99.99% |

| Density | 2.34 g/cm³ |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Electronegativity | NA |

Boron Sputtering Target

Boron sputtering targets are used in various applications due to boron’s unique properties, such as its hardness, ability to form compounds, and electrical characteristics. Here’s a detailed look at different product applications for boron sputtering targets.

Semiconductors

Doping Layers: Boron is widely used as a dopant in silicon to create p-type semiconductors. Sputtering targets are used to deposit boron films or layers that modify the electrical properties of semiconductor materials.

Gate Dielectrics: Boron-based thin films can be used as gate dielectrics in advanced semiconductor devices, offering high dielectric strength and stability.

Optical Coatings

Anti-Reflective Coatings: Boron thin films can be used to create anti-reflective coatings for lenses and optical components, improving their efficiency by reducing glare and reflection.

Protective Coatings: Boron coatings can protect optical surfaces from environmental damage, enhancing durability and lifespan.

Hard Coatings

Wear-Resistant Coatings: Due to its hardness, boron is used to deposit wear-resistant coatings on industrial tools, cutting tools, and other components that experience significant wear and tear.

Cutting Tools: Boron-based coatings improve the performance and durability of cutting tools by increasing hardness and reducing friction.

Thermal Barrier Coatings

High-Temperature Protection: Boron coatings can serve as thermal barriers in high-temperature applications, such as in aerospace or industrial processes, protecting components from extreme heat.

Ceramic and Composite Materials

Boron Carbide Formation: Boron sputtering targets are used in processes to form boron carbide (B₄C), a very hard ceramic material used in armor, cutting tools, and various industrial applications due to its hardness and lightweight properties.

Composite Materials: Boron-based films and coatings are used to enhance the mechanical and thermal properties of composite materials.

Nuclear Applications

Neutron Absorption: Boron is known for its neutron-absorbing properties. Boron sputtered films or coatings can be used in nuclear reactors for neutron control rods and shielding applications.

Battery Technologies

Electrode Coatings: Boron-based coatings are applied to electrodes in batteries to improve their performance, increase conductivity, or extend their lifespan.