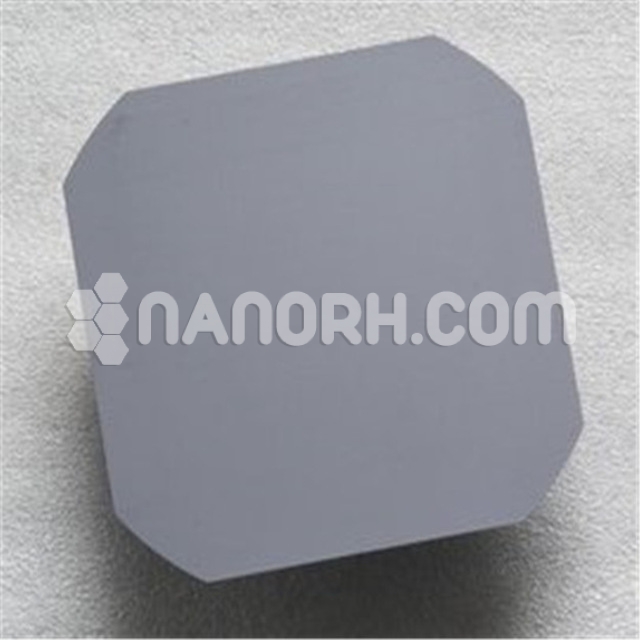

| TUNGSTEN Crucibles | |

| Product No | NRE-47010 |

| CAS | 7440-33-7 |

| Purity | >99.9% |

| Capacity | 5ml |

| Apparent Porosity | NA |

| Cold Bending Strength | NA |

| Max Service Temperature | 2450 °C |

| Density | 19.3 g/cm3 |

| Melting Point | 3410 °C |

| Boiling Point | 5900 °C |

TUNGSTEN Crucibles

Introduction:

TUNGSTEN crucibles are high-performance containers made from TUNGSTEN, a refractory metal renowned for its remarkable melting point (approximately 3,422°C or 6,192°F), exceptional strength, and resistance to thermal shock. These properties make TUNGSTEN crucibles ideal for a variety of applications that require high temperatures and inert environments. TUNGSTEN’s low thermal expansion and excellent thermal conductivity further enhance its suitability for demanding industrial processes.

Applications

Metallurgical Processes:

Melting and Casting: Widely used for melting high-temperature metals and alloys, such as titanium and molybdenum, where purity and resistance to contamination are critical.

Chemical Processing:

Employed in chemical reactions involving reactive materials, as TUNGSTEN’s inert nature prevents unwanted reactions and ensures the integrity of the contents.

High-Temperature Research:

Utilized in laboratories for high-temperature experiments and materials testing, particularly in fields such as materials science and physics, where precise temperature control is necessary.

Sintering of Ceramics:

Used in the sintering process for advanced ceramics and composite materials, providing a stable environment for achieving desired material properties.

Thin Film Deposition:

Applied in the semiconductor and electronics industries for physical vapor deposition (PVD) processes, where TUNGSTEN crucibles help produce high-quality thin films.

Nuclear Applications:

Employed in nuclear reactors for handling radioactive materials, where TUNGSTEN’s high melting point and low neutron absorption cross-section are advantageous.

Manufacturing of Superconductors:

Utilized in the production of superconducting materials, where high purity and thermal stability are required.

Thermal Management:

Applied in systems requiring effective heat dissipation, leveraging TUNGSTEN’s excellent thermal conductivity to manage temperatures efficiently.

Glass and Ceramic Production:

Used in the manufacturing of specialty glasses and ceramics, providing a stable environment for melting raw materials.

Pharmaceutical Applications:

Occasionally used in the pharmaceutical industry for processes requiring high temperatures and inertness, ensuring no contamination occurs.

Reviews

There are no reviews yet.