Highly Conductive Carbon Black & Graphene & Carbon Nanotubes Mixed

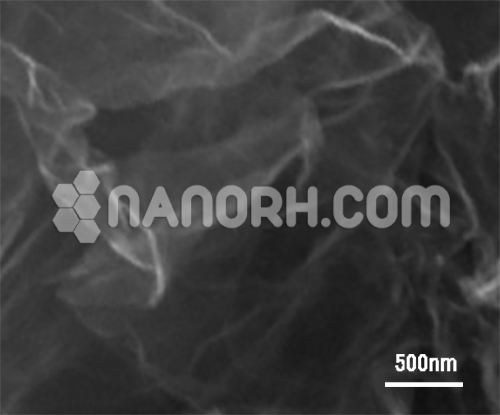

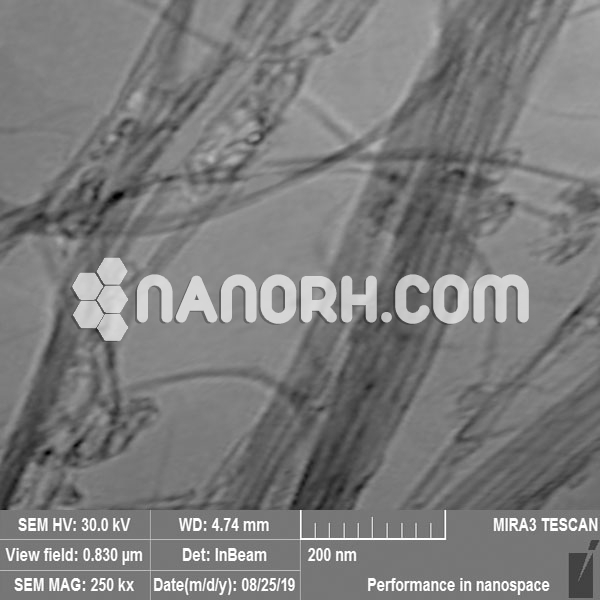

Effectively improve the electrical conductivity, thermal conductivity and mechanical properties; Effectively enhance tensile strength, hardness and elastic modulus characteristics. Also, Higher electrode conductivity and stronger electrode mechanical strength and adhesive attraction; The product is composed of high electric conductive CNTs and graphene and highly conductive carbon black nanopowder. The carbon black nanoparticles can not only prevent dispersed CNTs and graphene from reagglomerating, but also exhibit synergetic effect with CNTs and graphene

| Highly Conductive Carbon Black & Graphene & Carbon Nanotubes Mixed | |

| Product No | NRE-39017 |

| CAS No. | NA |

| Purity | > 97% |

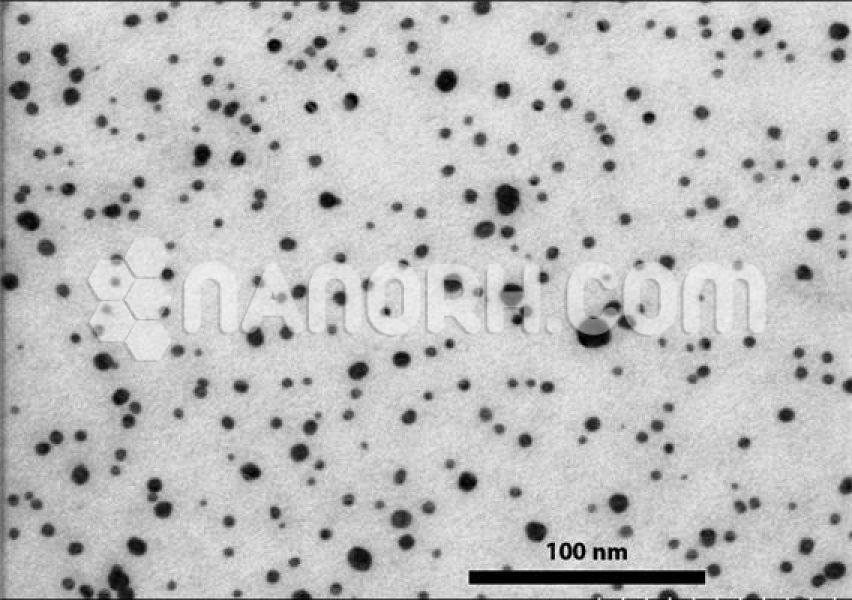

| Average Diameter | >55 nm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | > 60 m2/g (BET) |

| Tap Density | 0.12 g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | >100 s/cm |

Highly Conductive Carbon Black & Graphene & Carbon Nanotubes Mixed

Introduction

Highly conductive carbon black and graphene and carbon nanotubes mixed combines three distinct forms of carbon-based materials—carbon black, graphene, and carbon nanotubes—to create a composite material that maximizes the electrical conductivity, mechanical strength, and thermal properties of each component.

Applications:

The unique properties of enable its use in a variety of high-performance applications, particularly where electrical conductivity, mechanical strength, thermal management, and weight reduction are critical.

Electronics and Conductive Materials

Conductive Inks and Coatings: One of the most prominent uses of highly conductive carbon black, graphene, and CNT composites is in the development of conductive inks for printed electronics.

Flexible and Stretchable Electronics: For wearable devices and flexible displays, these composites provide both high conductivity and mechanical flexibility. The carbon nanotubes and graphene impart strength and flexibility, while carbon black provides cost-effective conductivity. This makes them ideal for wearable sensors, smart textiles, and other flexible electronics.

Electromagnetic Interference (EMI) Shielding: Carbon black, graphene, and CNT mixes are used in EMI shielding materials to protect sensitive electronic devices from electromagnetic interference.

Energy Storage and Batteries

Supercapacitors: Super capacitors, which store energy electrostatically, benefit significantly from the use of graphene and carbon nanotube composites. The combination of these materials increases the surface area and electrical conductivity, resulting in high-capacitance supercapacitors with fast charge/discharge cycles and long cycle life..

Lithium-Ion Batteries: For lithium-ion batteries, particularly in high-performance applications like electric vehicles or consumer electronics, a composite of carbon black, graphene, and CNTs is used to improve the electrical conductivity and energy storage capacity of the electrode materials.

Fuel Cells: In fuel cells, which convert chemical energy into electrical energy, graphene-CNT composites are used in the electrodes for better catalytic activity and electrical conductivity. The materials improve the performance of hydrogen fuel cells and direct methanol fuel cells, making them more efficient and cost-effective for renewable energy systems.

Thermal Management and Conductive Materials

Thermal Interface Materials (TIMs): The high thermal composite makes it ideal for thermal interface materials used in applications like power electronics, LED lighting, high-performance computers, and automotive electronics.