Highly Conductive Carbon Black & Graphene Mixed 20wt% in Water Dispersion

The product is composed of highly electric conductive graphene and highly conductive carbon black nanopowder. The carbon black nanoparticles can not only prevent dispersed graphene from reagglomerating, but also exhibit synergetic effect with graphene. By mixing the two conductive products, it can effectively improve the electrical conductivity, thermal conductivity and mechanical properties; effectively enhance tensile strength, hardness and elastic modulus characteristics, and provide higher electrode conductivity and stronger electrode mechanical strength and adhesive attraction

| Highly Conductive Carbon Black & Graphene Mixed 20wt% in Water Dispersion | |

| Product No | NRE-39020 |

| CAS No. | NA |

| Purity | >99wt% |

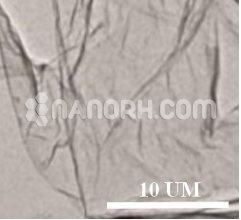

| Average Diameter | 1μm – 12μm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | 500-1200m2/g (BET) |

| Tap Density | NA |

| True Density | NA |

| Electric Conductivity | NA |

Highly Conductive Carbon & Graphene Mixed Water Dispersion

Introduction

Highly conductive carbon and graphene mixed water dispersion refers to a solution where carbon materials (such as carbon black or other conductive carbon forms) and graphene are dispersed in water. This dispersion combines the exceptional properties of graphene with the conductivity and stability of carbon-based materials, creating a versatile solution for various industrial applications.

Applications

The highly conductive carbon and graphene mixed water dispersion offers numerous advantages for industries requiring high-performance conductive materials. Below are key application areas where this dispersion is widely used:

Printed Electronics and Conductive Inks

Flexible Electronics: The mixture of graphene and carbon in water dispersion is used to create conductive inks for printed electronics, such as flexible circuits, printed antennas, RFID tags, and smart packaging. These inks can be applied to plastic or paper substrates, enabling the development of low-cost, flexible, and lightweight electronic devices.

Touchscreens and Sensors: This conductive dispersion can be applied to create transparent conductive coatings for devices like touchscreens or electronic displays. It can also be used in sensor networks for smart devices, wearable electronics, and Internet of Things (IoT) applications.

Smart Textiles: For wearable electronics embedded in fabrics, the carbon-graphene dispersion provides a flexible, stretchable, and conductive material that is perfect for integrating electronics directly into fabrics and textiles, enabling smart clothing and health-monitoring fabrics.

Electromagnetic Interference (EMI) Shielding

EMI Shielding Coatings: The high conductivity of this dispersion makes it ideal for EMI shielding applications. The composite can be applied as a coating on plastic housings, circuit boards, and electronic devices to protect them from electromagnetic interference. It is crucial for ensuring the proper functioning of sensitive electronics in environments with high levels of electrical noise, such as military electronics, smartphones, medical devices, and automotive electronics.

Automotive and Aerospace: In industries like automotive and aerospace, EMI shielding is essential for protecting critical systems such as navigation, communication, and control systems from interference. Graphene and carbon-based dispersions are ideal for lightweight, cost-effective shielding in such applications.