Graphitized MWNTs (>99.9%, OD: 50-80nm)

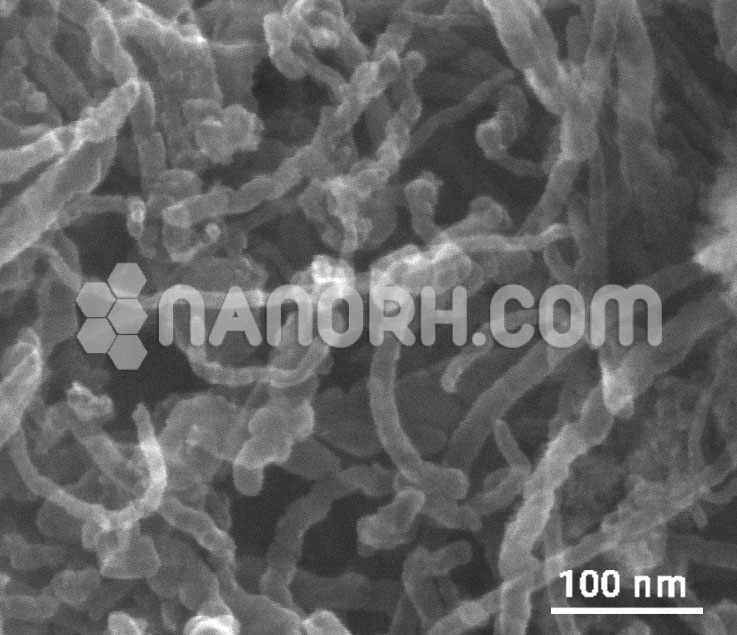

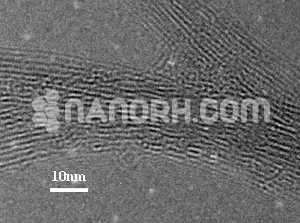

Graphitized high purity multi-walled carbon nanotubes (MWNTs) were produced by a low temperature CVD method and subsequently annealed about twenty (20) hours under condition of inert gas at temperatures between 1600 and 3000°C. These products were characterized for chemical purity, interlayer spacing, and defect healing. The graphitization procedure was found to remove residual metal catalyst in the nanotubes and reduce the wall defects as reflected in a reduced interlayer spacing between the graphene shells. The graphitized MWNTs have the highest graphite crystallization, the high electrical conductivity and the excellent inoxidizability. The electrical conductivity of the graphitized MWNTs is very close to that of graphite powder. And its ignition temperature can reach 800°C.

| Graphitized MWNTs | |

| Product No | NRE-40006 |

| CAS No. | NA |

| Purity | Carbon nanotubes > 99.9wt% |

| Average Diameter | 50-80 nm |

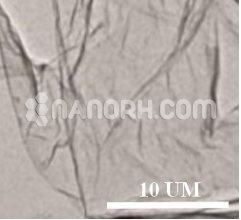

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | >20m2/g(BET) |

| Tap Density | NA |

| True Density | 2.1g/cm3 |

| Electric Conductivity | > 100 S/cm |

Graphitized MWNTs (>99.9%, OD: 50-80nm)

Applications

Composite Materials

Polymer Nanocomposites: Graphitized MWNTs are used as reinforcement agents in polymer nanocomposites. The high aspect ratio and improved dispersibility, thanks to the graphitization process, enhance the mechanical strength, electrical conductivity, and thermal conductivity of the polymer. Applications include:

Aerospace and automotive components, where lightweight, high-strength, and thermally stable materials are essential.

Consumer electronics, such as casings for mobile phones and laptops, where conductivity and heat dissipation are important.

Sports equipment, such as high-performance tennis rackets, golf clubs, and bicycles.

Metal Matrix Composites: Graphitized MWNTs can be incorporated into metal matrices to enhance the mechanical and thermal properties of metals used in industries like aerospace, automotive, and manufacturing. The graphitized MWNTs improve the material’s thermal conductivity, wear resistance, and mechanical strength.

Ceramic Matrix Composites: Graphitized MWNTs are used to reinforce ceramic materials, which are inherently brittle. They improve the fracture toughness, thermal conductivity, and strength of ceramics in applications such as cutting tools, engine components, and heat shields.

Energy Storage and Conversion

Supercapacitors: Due to their high surface area, excellent conductivity, and mechanical stability, graphitized MWNTs are used in supercapacitor electrodes. They enable high energy storage and fast charge/discharge rates, making them ideal for:

Electric vehicles (EVs) and hybrid electric vehicles (HEVs), where quick bursts of energy are needed.

Portable electronics (e.g., smartphones, tablets) for long battery life and fast recharging capabilities.

Renewable energy storage, such as in solar or wind power systems, to store energy and provide backup power.

Lithium-Ion Batteries: In lithium-ion batteries, graphitized MWNTs are used as anode or cathode materials to improve the electrical conductivity and cycle stability. This enhances the overall energy density, charge retention, and lifetime of the batteries, which are widely used in:

Electric vehicles (EVs).

Consumer electronics (e.g., laptops, smartphones).

Grid-scale energy storage systems.

Fuel Cells: Graphitized MWNTs are used as catalyst supports or electrocatalysts in proton exchange membrane (PEM) fuel cells. They improve the performance of reactions such as hydrogen oxidation and oxygen reduction. Applications include:

Hydrogen-powered vehicles.

Portable power sources.

Backup power systems.

.