| Ni-Cr Alloy Nanoparticles | |

| Product No | NRE- 2032 |

| CAS No. | 11106-97-1 |

| Formula | Ni-Cr |

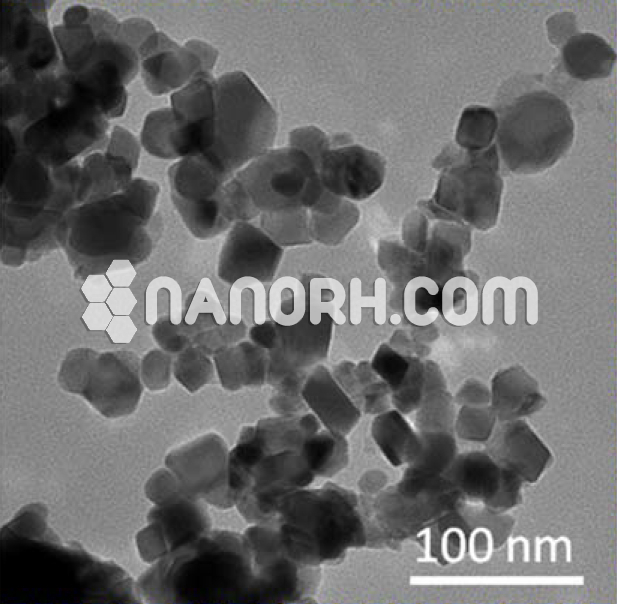

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey Black |

| Molecular Weight | 110.6895 g/mol |

| Density | NA |

| Melting Point | 1400°C |

| Boiling Point | NA |

Ni/Cr Alloy Nanopowder

Ni/Cr Alloy Nanopowder/Nanoparticles

Nickel-chrome alloys gained importance in the 1930s due to the cost of gold. Ni-Cr alloys have properties suitable for use with ceramics. The hardness and elastic modulus of the Ni-Cr alloy allow the use of a thinner cross-section of the material; The thinner cross-section offers more room for porcelain cladding and offers good resistance. Another advantage is its linear thermal expansion coefficient, which is similar to that of porcelain cladding.

Introduction

Ni/Cr alloy nanopowder is a combination of Nickel (Ni) and Chromium (Cr) in the form of nanoparticles. Nickel and chromium, both highly valued metals, are commonly used in alloys for their exceptional mechanical, chemical, and thermal properties. When combined into an alloy, they exhibit a unique set of characteristics that make them highly valuable for many industrial and technological applications.

Nickel (Ni): A versatile metal, nickel is known for its corrosion resistance, high thermal stability, and ability to form durable alloys. In an alloy, it enhances strength, ductility, and resistance to oxidation.

Chromium (Cr): Chromium is renowned for its exceptional resistance to corrosion, particularly in harsh environments. It also contributes to the alloy’s hardness and wear resistance.

Synthesis

The synthesis of Ni/Cr alloy nanopowders typically involves methods that ensure precise control over the size, shape, and composition of the nanoparticles. Common techniques include:

Mechanical Alloying (Ball Milling): This is a widely used method for producing Ni/Cr alloy nanopowders. By grinding Ni and Cr powders together in a high-energy ball mill, nanoparticles of the alloy are formed. This technique helps achieve fine particle sizes and uniform distribution of elements in the powder.

Chemical Vapor Deposition (CVD): CVD is used to deposit Ni and Cr onto a substrate or in a gas phase, resulting in the formation of fine nanoparticles. This method allows precise control over the nanoparticle size and morphology.