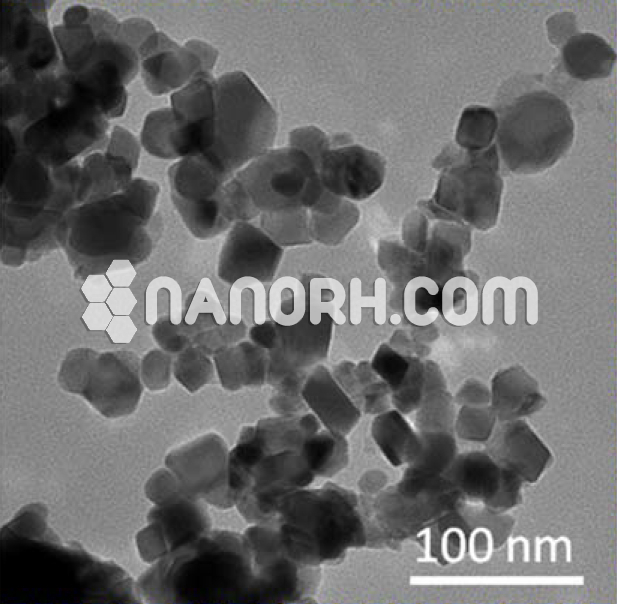

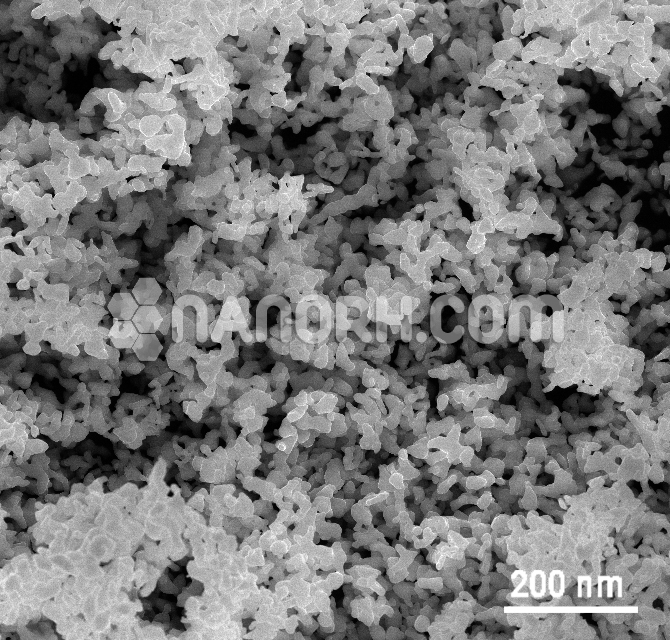

Sn-Cu Alloy Nanopowder / Nanoparticles (99.9%, <100nm, SN:CU/9:1)

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the product should be avoided under stress

| Sn-Cu Alloy Nanopowder / Nanoparticles (99.9%, <100nm, SN:CU/9:1) | |||||||

|---|---|---|---|---|---|---|---|

| Product No. | CAS No. | Formula | Molecular Weight | APS | Purity | Color | Form |

| NRE-2013 | 7440-31-5/7440-50-8 | Sn-Cu Alloy Nanopowder | 182.256 g/mol | <100nm (Can be Customized) | 99.9% | Grey Black | Powder |

| Density | NA | ||||||

| Melting Point | NA | ||||||

| Boiling Point | NA | ||||||

Sn-Cu Alloy Nanoparticles

Three types of free ligands Sn-Cu nanoporous alloys are prepared by electrodeposition, then distributed and electrochemically tested as possible materials for negative electrodes of lithium ion batteries. The morphology and structure of these alloys have been characterized by X-ray diffraction, scanning electron microscopy, and atomic absorption spectrophotometer. Experimental results indicate that the composition, pore size, size distribution, and alloy homogeneity can be controlled easily by changing the proportion of primary salts in the plating bath. The content of Sn in the alloys after an electrochemical sale is significantly reduced and Cu6Sn5 becomes the main active component. However, there is no obvious decrease in specific capacity. The initial specific capacities of all materials are in the range 480-810 mA h g-1. But the ability of the deposited Sn-Cu alloys remains 110-190 mA h g-1 after 50 cycles, while a capacity of Sn-Cu nanoporous alloys remains approximately 400 mA hg-1 after the same cycles. This suggests that both the capacity and performance of the cycle can be improved by optimizing the nanostructured materials using electrochemical distribution.