| Tungsten Titanium Carbide Powder | |

| Product No | NRE-5247 |

| CAS No. | 39377-63-4 |

| Formula | WCTiC |

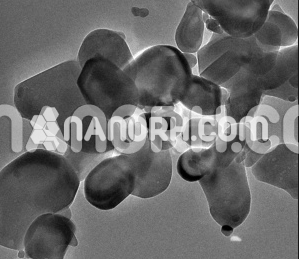

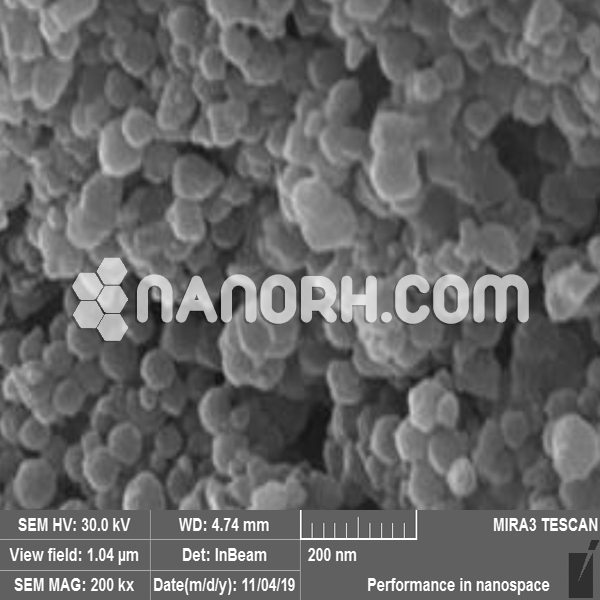

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray |

| Molecular Weight | 243.72 g/mol |

| Density | NA |

| Melting Point | NA |

| Boiling Point | NA |

Tungsten Titanium Carbide Powder WC:TiC=50:50

Applications

The unique combination of hardness, wear resistance, and high-temperature stability of tungsten titanium carbide powder makes it useful in a range of applications, especially in industries where high performance under extreme conditions is required.

Cutting Tools and Abrasives

Tungsten titanium carbide powder is used in the manufacturing of cutting tools and abrasives because of its superior hardness and wear resistance.

Metal Cutting Tools: tungsten titanium carbide is used in the production of cutting tools, such as drills, mills, and taps, which are essential for machining hard materials like metals, ceramics, and composites. The hardness of WTiC allows these tools to last longer and maintain their sharpness under harsh conditions.

Grinding and Polishing: The hardness and abrasive properties of tungsten titanium carbide are leveraged in grinding wheels, abrasive pads, and polishing compounds. These applications benefit from WTiC’s ability to withstand high stress and abrasion.

Aerospace and Defense

In the aerospace and defense industries is used for high-performance applications that require durability, wear resistance, and resistance to extreme conditions.

Aerospace Components: tungsten titanium carbide is used in aerospace components that must withstand high temperatures, wear, and thermal cycling, such as turbine blades, nozzles, and heat shields. The combination of high hardness and thermal stability ensures the longevity and efficiency of these components in the harsh conditions of jet engines and rocket propulsion systems.

Mining and Oil & Gas Industry

The hardness and wear resistance of WTiC Tungsten titanium carbide make it highly effective in tools used in mining and oil extraction, where harsh environmental conditions and heavy wear are common.