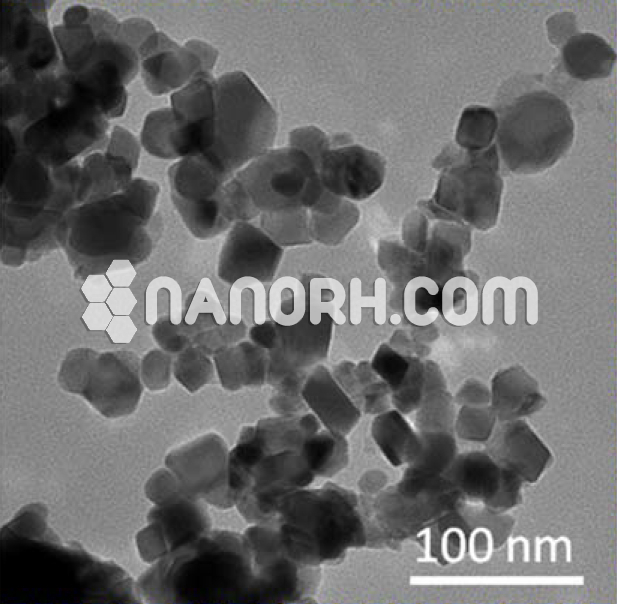

Zirconia Toughened Alumina (ZTA) Nanopowder / ZTA Nanoparticles, 800nm, 99.9%, 30% Zirconia ZrO-Al2O3

With better durability, better quality, better erosion protection, better concoction solidness – Alumina has great hardness attributes, zirconia has great sturdiness qualities, the two materials to shape a high-quality, high strength of the phenomenal buildings. Room temperature has high bowing quality and crack durability, so zirconia toughening pottery has astounding wear protection. Additionally, ZTA powder doped with a little…………..

| Zirconia Toughened Alumina Nanopowder | |

| Product No | NRE-4023 |

| CAS No. | NA |

| Formula | ZrO-Al2O3 |

| APS | <800nm (Can be Customized) |

| Purity | 99.9% |

| Color | White |

| Molecular Weight | 101.96 g/mol |

| Density | 3.95 g/cm3 |

| Melting Point | 2,072° C |

| Boiling Point | 2,977° C |

Zirconia Toughened Alumina (ZTA) Nanopowder/ZTA Nanoparticles, Average Particles Size 800nm, 99.9%, 30% Zirconia ZrO-Al2O3

ZrO2 toughened alumina artistic mechanical properties: ZTA (zirconia toughened alumina) fired thickness ≥ 4.15, Rockwell hardness ≥ 90, Vickers hardness ≥ 1350, crack sturdiness 6.0, flexural quality >550MPa, compressive quality > 3800Ma.

Applications

Structural Ceramics

Cutting Tools: ZTA nanopowder is used to produce cutting tools such as milling cutters, drills, saw blades, and abrasive tools. Its excellent hardness and wear resistance make it ideal for machining tough materials, such as metals and composites, in industries like manufacturing, automotive, and aerospace.

Grinding Media: ZTA is used as grinding media in ball mills and other grinding equipment due to its high hardness and wear resistance. The nanopowder is formulated into ceramic beads or other shapes for use in the mineral processing industry, where it helps grind materials more efficiently while minimizing wear on the equipment.

Ball Bearings: ZTA nanopowder is also used in the manufacture of high-performance ball bearings and other components for rotary equipment. Its combination of hardness and toughness enhances the performance and longevity of bearings, even under heavy load and high-speed conditions.

Biomedical Applications

Dental Materials: ZTA is widely used in dental implants, crowns, and braces due to its biocompatibility, fracture toughness, and wear resistance. Zirconia is often used in combination with alumina to provide a material that mimics the strength and durability of natural teeth. The use of ZTA in dental prosthetics allows for long-lasting, aesthetic restorations that are resistant to wear and cracking under the stress of biting.

Orthopedic Implants: ZTA is used in the development of joint replacements, such as hip and knee implants, due to its strength, toughness, and resistance to wear. It provides a reliable alternative to traditional materials such as metal alloys and is especially beneficial in high-load bearing applications.

Bone Substitutes: ZTA nanopowder is being explored as a material for bone scaffolds and bone repair. Its excellent mechanical properties make it suitable for use in load-bearing bone replacements or for supporting bone regeneration in orthopedic surgeries.