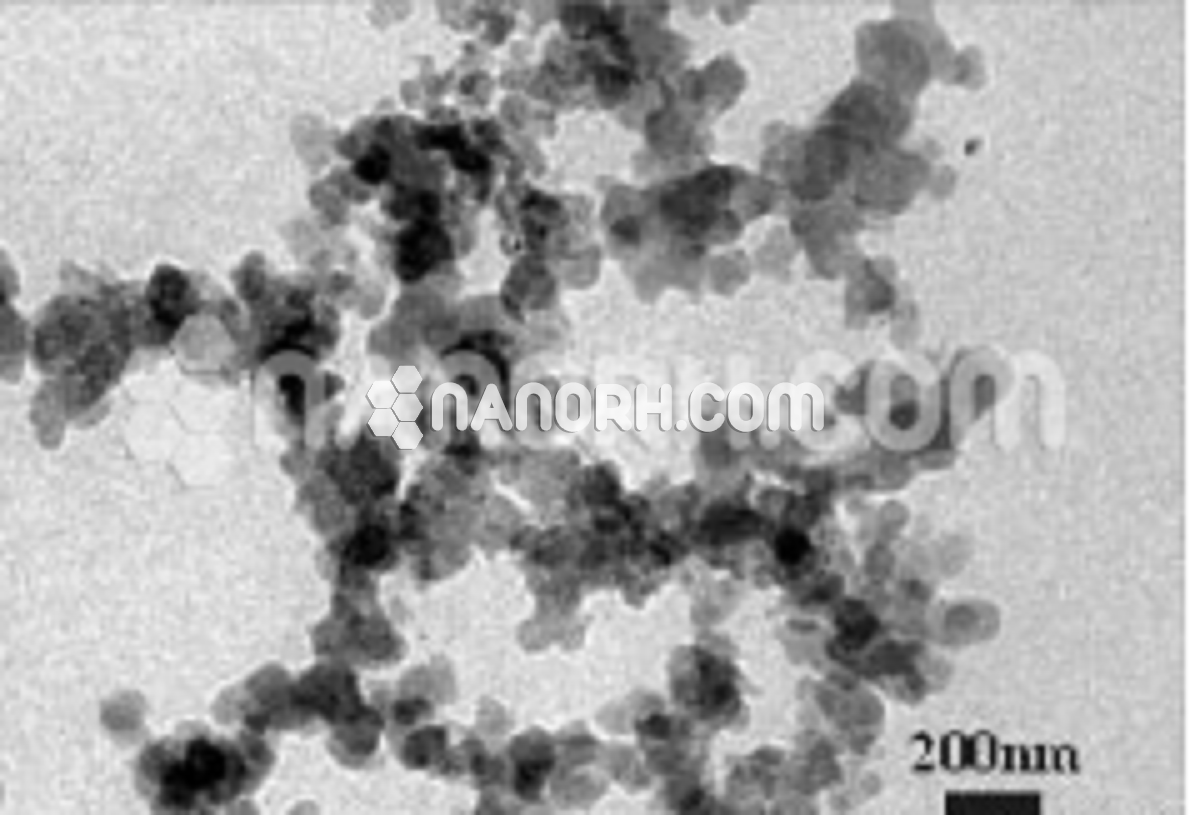

Si3N4 Nanoparticles / Nanopowder (Si3N4, 99+%, 80nm, amorphous)

The item has high virtue, limit extend molecule measure dispersion, and bigger particular surface territory; 2. the hardness of this item is around 9 to 9.5, Knoop hardness is around 2200, microhardness is 32630Mpa, softening point is 1900 °C (under weight) and warm conductivity rate is 16.7W/(m · K). It doesn’t break up in water, dissolvable in hydrofluoric corrosive; 3. Nano-silicon nitride modulus: 28420 ~ 46060Mpa; twisting quality: 147MPa; compressive quality: 490MPa (response sintering). It is an imperative auxiliary earthenware materials and a super-hard material. The item itself has grease, wear protection, erosion protection, against oxidation in high temperature. What’s more, it can withstand the hot and icy stun. On the off chance that it is warmed to over 1000 °C noticeable all around, and after that quickly cooled and took after by quickly………

| Si3N4 Nanoparticles | |

| Product No | NRE-5195 |

| CAS No. | 12033-89-5 |

| Formula | Si3N4 |

| APS | <80nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey |

| Molecular Weight | 140.2833 g/mol |

| Density | 3.17g/cm3 |

| Melting Point | 1,900 °C |

| Boiling Point | NA |

Silicon Nitride Nanoparticles (Si3N4) General Features:

1. The item has high virtue, limit extend molecule measure dispersion, and bigger particular surface territory; 2. the hardness of this item is around 9 to 9.5, Knoop hardness is around 2200, microhardness is 32630Mpa, softening point is 1900 °C (underweight) and warm conductivity rate is 16.7W/(m · K). It doesn’t break up in the water, dissolvable in hydrofluoric corrosive; 3. Nano-silicon nitride modulus: 28420 ~ 46060Mpa; twisting quality: 147MPa; compressive quality: 490MPa (response sintering). It is an imperative auxiliary earthenware material and a super-hard material. The item itself has grease, wear protection, erosion protection, against oxidation at high temperatures. What’s more, it can withstand the hot and icy stun. On the off chance that it is warmed to over 1000 °C noticeable all around, and after that quickly cooled and took after by quickly warmed once more, it won’t break. Moreover, the clay framing temperature of silicon nitride fired gadgets is low. Silicon nitride fired gadgets have great dimensional steadiness and high mechanical quality.

Silicon Nitride Nanoparticles (Si3N4) Applications:

This item is fundamentally utilized for: 1) producing structure gadget, for example, metallurgy, synthetic industry, apparatus, flying, aviation, and vitality businesses to utilize the ball and roller bearing, sliding bearing, sleeve, valve, and a wear-safe, high temperature, erosion safe auxiliary parts required. 2) Surface treatment of metal and different materials, for example, molds, cutting instruments, turbine sharp edges, turbine rotor, and the barrel divider coatings. 3) Composite materials, for example, metals, earthenware production, and graphite composites, elastic, plastics, coatings, cement and other polymer-based composites. 4) The dull, straightforward self-greasing up wear-safe nano-molecule films for cell phones, autos, and other propelled surface assurance. 5) Ball course 6) Ball valves and parts 7) Corrosion safe turbine 8) Cutting apparatuses Grinding wheels 9) Insulating parts 10) Spray spouts (for rockets) 11) Spray pipe (for rockets) 12) Strengthening materials (for Al and so forth) 13) Wear parts… …

Silicon Nitride Nanoparticles (Si3N4) Storage Conditions:

The sodden get-together will influence its scattering execution and utilizing impacts, along these lines, this item ought to be fixed in a vacuum and put away in a cool and dry room and it ought not to be the presentation to air. Furthermore, the item ought to have stayed away from under anxiety.