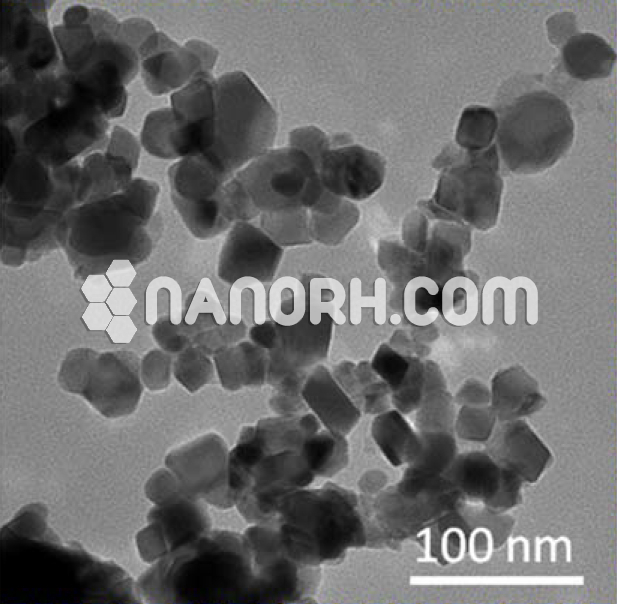

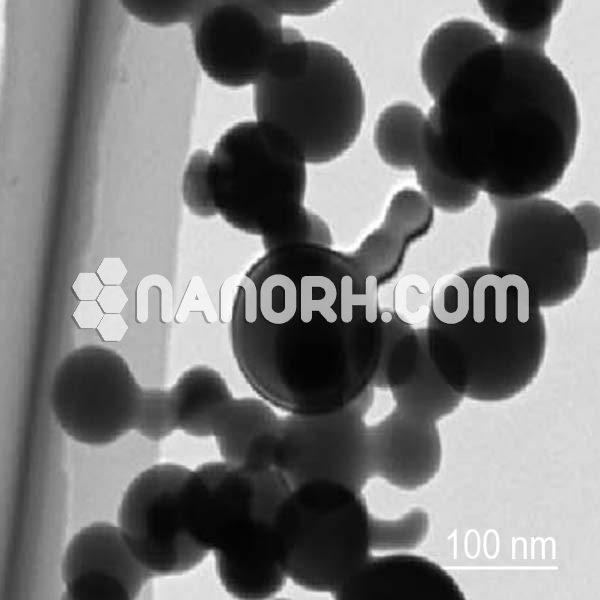

Molybdenum Disilicide Nanopowder / MoSi2 Nanoparticles (MoSi2, 300nm, 99.9%)

The fundamental qualities of molybdenum disilicide powder: molybdenum disilicide artistic powder is a dim powder, concoction recipe: MoSi2, atomic weight: 152.11, thickness: 6.3g/cm3, coefficient of warm extension: 5.1 × 10-6K-1, protection rate: 21 × 10-6ω.cm, microhardness 1200kg/mm2. high softening point, high consumption protection, high oxidation protection, great electrical conductivity, high temperature malleability, a parallel amalgam systemthe moderate stage

| Molybdenum Disilicide (MoSi2) Nanopowder | |

| Product No | NRE-5162 |

| CAS No. | 12136-78-6 |

| Formula | MoSi2 |

| APS | <300nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray Black |

| Molecular Weight | 152.111 g/mol |

| Density | 6.26 g/cm³ |

| Melting Point | 2,030 °C |

| Boiling Point | NA |

Molybdenum Disilicide (MoSi2) Nanopowder

The fundamental qualities of molybdenum disilicide powder: molybdenum disilicide artistic powder is a dim powder, concoction recipe: MoSi2, atomic weight: 152.11, thickness: 6.3g/cm3, coefficient of warm extension: 5.1 × 10-6K-1, protection rate: 21 × 10-6ω.cm, microhardness 1200kg/mm2.

High-Temperature Structural Materials:

Refractory Coatings: MoSi2 is widely used in high-temperature coatings and materials due to its ability to withstand extreme temperatures (over 1500°C). The nanopowder form can be used to coat components exposed to high heat, such as turbine blades and heating elements.

Heat-Resistant Components: MoSi2 nanopowders are used to create components for high-temperature industrial processes, including those in aerospace, gas turbines, and power generation. These materials maintain their structural integrity and strength at elevated temperatures.

Electrical Heating Elements:

Heating Elements in Furnaces: MoSi2 is commonly used in electric heating elements for furnaces, kilns, and other high-temperature environments. The nanopowder form allows for enhanced performance by increasing surface area, leading to more efficient heating and improved longevity of the elements.

Thermal Barriers and Insulation:

Thermal Protection Systems: The high thermal stability and resistance to oxidation of MoSi2 make it ideal for use in thermal protection systems (TPS) for aerospace applications, such as spacecraft reentry systems. Nanopowders enhance the properties of MoSi2 by promoting uniform coatings with better thermal insulation.

Insulating Materials for High-Temperature Electronics: MoSi2 nanopowders are also utilized as insulating materials in high-temperature electronics, especially in devices that need to operate under extreme conditions.

Wear-Resistant Coatings:

Tribological Applications: MoSi2 nanopowder is used to create wear-resistant coatings for components subject to high friction and wear, such as bearings, gears, and engine parts. These coatings improve the durability and lifespan of mechanical parts by reducing wear and tear.

Tooling Applications: The nanopowder form of MoSi2 can be used to fabricate cutting tools, molds, and dies that are exposed to high stress and temperature, offering significant improvements in performance.