Zirconia Toughened Alumina (ZTA) Nanopowder / ZTA Nanoparticles, 80nm, 99.9%, 30% Zirconia ZrO-Al2O3

ZrO2 toughened alumina earthenware mechanical properties: ZTA (zirconia toughened alumina) clay thickness ≥ 4.15, Rockwell hardness ≥ 90, Vickers hardness ≥ 1350, break durability 6.0, flexural quality >550MPa, compressive quality > 3800MPa

With better sturdiness, better quality, better consumption protection, better synthetic security

| Zirconia Toughened Alumina Nanopowder | |

| Product No | NRE-4023 |

| CAS No. | NA |

| Formula | ZrO-Al2O3 |

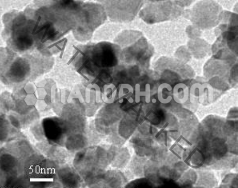

| APS | <80nm (Can be Customized) |

| Purity | 99.9% |

| Color | White |

| Molecular Weight | 101.96 g/mol |

| Density | 3.95 g/cm3 |

| Melting Point | 2,072° C |

| Boiling Point | 2,977° C |

Zirconia Toughened Alumina (ZTA) Nanopowder/ZTA Nanoparticles, 80nm, 99.9%, 30% Zirconia ZrO-Al2O3

Zirconia toughened alumina nanopowder / ZTA nanoparticles Average Particles Size 80nm, 99.9%, 30% Zirconia ZrO-Al2O3 ZrO2 toughened alumina earthenware mechanical properties: ZTA (zirconia toughened alumina) clay thickness ≥ 4.15, Rockwell hardness ≥ 90, Vickers hardness ≥ 1350, break durability 6.0, flexural quality >550MPa, compressive quality > 3800MPa.

Key Properties

Increased Toughness:

The addition of Zirconia toughened alumina nanopowder / ZTA nanoparticles introduces a mechanism known as toughening. Zirconia undergoes a phase transformation from tetragonal to monoclinic under stress, which generates compressive stresses that inhibit crack propagation, leading to an increase in fracture toughness.

High Strength and Hardness:

ZTA nanopowder combines the hardness of alumina with the toughness of zirconia, making it suitable for high-stress applications where both hardness and resistance to crack propagation are critical.

Excellent Wear Resistance:

Due to its hardness and toughness, ZTA nanopowder is highly resistant to wear and abrasion, which is why it is used in demanding industrial applications where wear resistance is essential.

Thermal Stability:

ZTA nanopowder exhibits excellent resistance to thermal shock and high-temperature stability. This makes it ideal for applications in high-temperature environments, such as in aerospace, automotive, and energy industries.

Corrosion Resistance:

ZTA nanopowder also offers high resistance to corrosion, particularly in acidic and alkaline environments, which is important for many industrial applications, including chemical processing and biomedical devices.

Electrical Insulation:

Both alumina and zirconia are electrical insulators, and when combined, Zirconia toughened alumina nanopowder / ZTA nanoparticles maintains excellent insulating properties, making it suitable for use in electronic components where electrical conductivity is not desired.