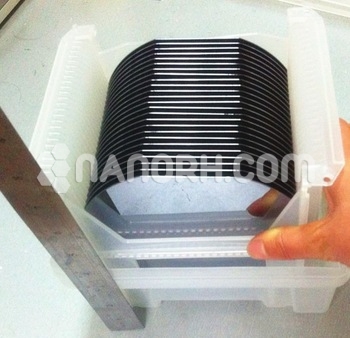

| Fe50Co50 sputtering target | |

| Product No | NRE-43637 |

| CAS No. | NA |

| Formula | NA |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Fe50Co50 sputtering targets

The Fe50CO50 alloy sputtering target, with its specific composition, is designed for a variety of advanced material applications. Here’s a breakdown of the composition and potential applications.

Composition:

Fe5: 5% Iron (Fe)

O: Oxygen (O)

Co50: 50% Cobalt (Co)

Properties:

Iron: Iron contributes to the magnetic properties and can influence the structural characteristics of the alloy.

Cobalt: With 50% cobalt, the alloy has significant magnetic properties, including high saturation magnetization and permeability.

Oxygen: Oxygen can form oxides with iron and cobalt, potentially affecting the alloy’s structural and magnetic properties.

Potential Applications:

Magnetic Thin Films: The high cobalt content suggests that the sputtered films would have strong magnetic properties. These films are useful in various magnetic applications, such as magnetic sensors, actuators, and components for data storage devices.

Hard Coatings: The alloy’s combination of iron and cobalt, along with potential oxide formation, might be used to create hard coatings with improved wear resistance and durability. These coatings can be applied to tools, machinery, and other surfaces requiring enhanced hardness.

Magnetic Recording Media: The alloy’s magnetic properties make it suitable for applications in magnetic recording media. This includes hard disk drives and other data storage technologies where magnetic materials are critical.

Electromagnetic Interference (EMI) Shielding: Due to its magnetic properties, the alloy could be used for shielding applications, where it helps block or absorb electromagnetic interference, protecting sensitive electronic components.

Catalysts and Sensors: Depending on the specific form of the alloy and its oxide components, it could be used in catalytic applications or as part of sensors for detecting various chemical or physical properties.

Research and Development: The unique composition of the Fe5OCO50 alloy makes it a candidate for R&D, where researchers might explore its properties for new technologies or innovative applications in materials science.