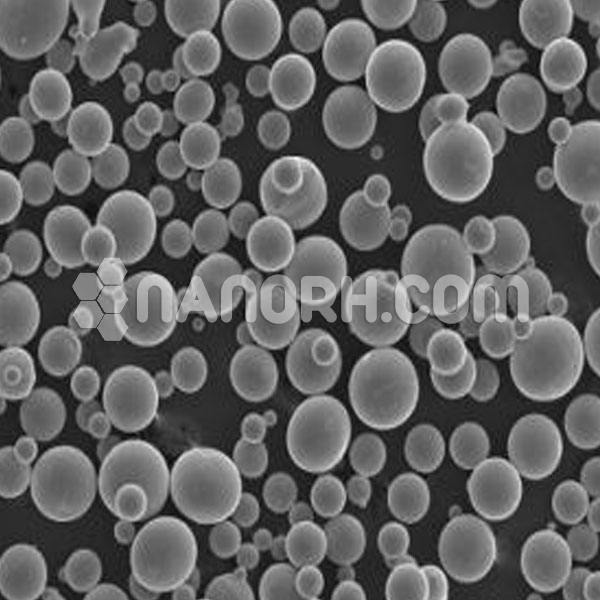

Magnesium Spherical Powder

Magnesium spherical powder is a finely divided form of magnesium that has been processed to achieve a spherical shape. This unique morphology enhances its flowability, packing density, and reactivity, making it particularly valuable in various industrial applications. Magnesium is a lightweight metal known for its excellent strength-to-weight ratio, corrosion resistance, and ability to form alloys, which further broadens its applicability.

Applications

Additive Manufacturing:

Magnesium spherical powder is widely used in metal 3D printing processes, such as selective laser melting (SLM) and electron beam melting (EBM). Its flowability and spherical shape facilitate layer-by-layer deposition, enabling the creation of complex geometries.

Aerospace and Automotive Industries:

In these sectors, magnesium is used to produce lightweight components that improve fuel efficiency. Spherical powder can be utilized for die casting and powder metallurgy to manufacture parts with excellent mechanical properties.

Chemical Reactions:

Due to its high reactivity, magnesium spherical powder is used in various chemical reactions, including the production of magnesium alloys and in pyrotechnics.

Battery Technology:

Magnesium is being researched as a potential anode material in rechargeable batteries. Spherical magnesium powder can enhance battery performance and energy density.

Thermal Management:

Magnesium’s excellent thermal conductivity makes it suitable for applications in thermal management systems, where efficient heat dissipation is essential.

Biocompatible Applications:

Due to its biocompatibility, magnesium is explored in biomedical applications, such as temporary implants that degrade over time within the body.

Coatings and Surface Treatments:

Magnesium powders are used in various coating processes, enhancing surface properties such as wear resistance and corrosion protection.

| Spherical magnesium powder | |

| Product No | NRE-60104 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Commodity name | Spherical magnesium powder |

| Manufacturing method | centrifugal atomization |

| Appearance | silver grey spherical powder |

| PSD | 20-500mesh |

| Purity | 99.9%min |

| Package | 0.5-5kg/bag or 50-200kg/drum |

| Shape | spherical | |

| Proportion of Sphere /% | ≥95 | |

| Apparent density/g·cm-3 | 0.90(min) | |

| Real density/g·cm-3 | 1.73 | |

| Fluidity/s·(50g)-1 | 78.6 | |

| Moisture absorption rate /% | 0.01 | |

| Active Mg content /% | 99.0(min) | |

| Calorific value/kJ/g | 26.09 | |

| Calorific density/kJ/cm3 | 45.39 | |

|

Impurity

content

/% |

Moisture/%(max) | 0.05 |

| Insoluble material in HCl /%(max) | 0.13 | |

| Oil & grease/%(max) | 0.00 | |

| Fe/%(max) | 0.01 | |

| Mn/%(max) | 0.008 | |

| Zn/%(max) | 0.008 | |

| Cl/%(max) | 0.003 | |

Spherical magnesium powder

Applications

Additive Manufacturing (3D Printing):

Processes: Selective Laser Melting (SLM), Electron Beam Melting (EBM), Direct Energy Deposition (DED)

Applications:

Aerospace: Lightweight structural parts, engine components, and frames for aircraft and spacecraft, where reducing weight can significantly enhance fuel efficiency.

Automotive: Components like brackets, engine parts, and transmission components, where reducing weight improves performance and fuel economy.

Advantages: Spherical magnesium powder is ideal for 3D printing as it enables high-resolution, complex geometries with reduced post-processing, improving design flexibility and material efficiency.

Powder Metallurgy (PM):

Applications:

Automotive: Parts like gears, brakes, bearings, and chassis components, where weight reduction is important for improving vehicle performance and fuel efficiency.

Aerospace: Lightweight structural components, such as frames, brackets, and mountings, to reduce the overall weight of aircraft.

Thermal Spray Coatings:

Applications:

Corrosion-resistant coatings for parts exposed to harsh environments, such as marine equipment, automotive exhaust systems, and industrial machinery.

Wear-resistant coatings for turbines, machine tools, and engine components.

Process: Spherical magnesium powder is used in thermal spraying techniques like plasma spraying, flame spraying, and HVOF (High-Velocity Oxygen Fuel), which apply a protective coating to metal surfaces.

Advantages: The powder can provide long-lasting protection from corrosion and wear while maintaining thermal conductivity and light weight.

Die-Casting:

Applications:

Automotive: Components such as engine blocks, wheels, brake components, and gearboxes to reduce weight and enhance vehicle performance.

Aerospace: Aircraft frames, turbine components, and engine parts.

Advantages: Spherical magnesium powder can be used in die-casting processes to produce complex, thin-walled components with high dimensional accuracy, low porosity, and light weight.

Metal Injection Molding (MIM):