| Mg-Al alloy powder spherical | |

| Product No | NRE-60103 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Shape | spherical | |

| The proportion of Sphere /% | ≥95 | |

| Apparent density /g·cm-3 | 1.236 | |

| Real density /g·cm-3 | 2.1153 | |

| Fluidity /s·(50g)-1 | 53 | |

| Moisture absorption rate /% | 0.01 | |

| Active Mg+Al content /% | 99.25 | |

| Calorific value kJ/g | 23.26 | |

|

Impurity

content

/% |

Moisture/%(max) | 0.05 |

| Insoluble material in HCl /%(max) | 0.13 | |

| Oil & grease /%(max) | 0.00 | |

| Fe/%(max) | 0.05 | |

| Mn/%(max) | 0.01 | |

| Zn/%(max) | 0.01 | |

| Cl/%(max) | 0.003 | |

Mg-Al alloy powder spherical

Introduction to Spherical Mg-Al Alloy Powder:

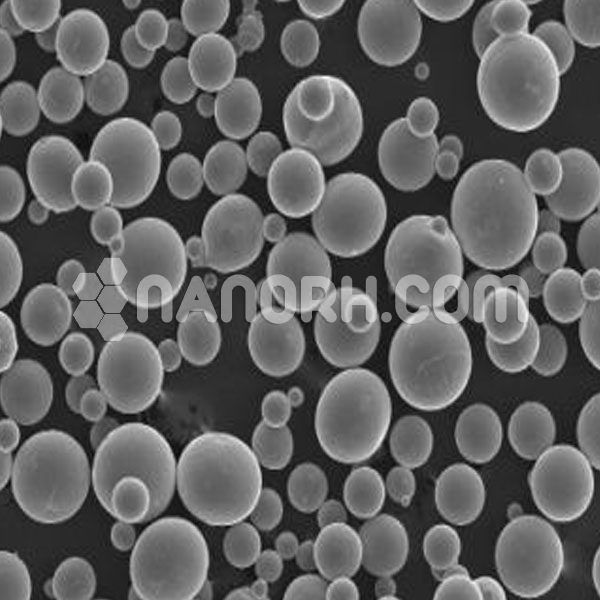

Spherical Magnesium-Aluminum (Mg-Al) Alloy Powder is a specialized type of powder produced by atomizing a mixture of magnesium and aluminum metals. The atomization process results in the production of fine, spherical powder particles, which offer superior flowability and uniformity compared to irregularly shaped powders. This spherical form is highly valued in various advanced manufacturing processes, such as additive manufacturing (3D printing), powder metallurgy, and metal injection molding.

The Mg-Al alloy itself combines the lightweight properties of magnesium with the strength and improved corrosion resistance offered by aluminum. These alloys are typically found in a range of compositions, such as AZ91D (which contains 9% aluminum and 1% zinc), and are utilized in numerous applications due to their excellent mechanical properties, durability, and low density.

Features of Spherical Mg-Al Alloy Powder:

Spherical Shape: The spherical shape of the powder provides excellent flowability and packing density, making it ideal for additive manufacturing (like Selective Laser Melting or Electron Beam Melting) and other powder-based manufacturing methods.

Lightweight: Magnesium is the lightest structural metal, and the addition of aluminum keeps the overall weight low while maintaining strength.

Improved Corrosion Resistance: The aluminum component enhances the powder’s ability to resist corrosion, making it suitable for marine, aerospace, and automotive applications where components are exposed to harsh environments.

Strength-to-Weight Ratio: Mg-Al alloy powder has a high strength-to-weight ratio, making it useful for lightweight components that still require high mechanical strength.

Thermal and Electrical Conductivity: Both magnesium and aluminum contribute to the good thermal conductivity of the alloy, which is beneficial for applications in heat dissipation systems and electronic devices.