| Atomized spherical Mg-Al alloy powder | |

| Product No | NRE-60103 |

| Purity | 99.9% |

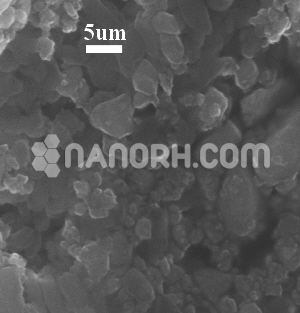

| Mesh | 30-500 mesh |

| Color | Silver Gray |

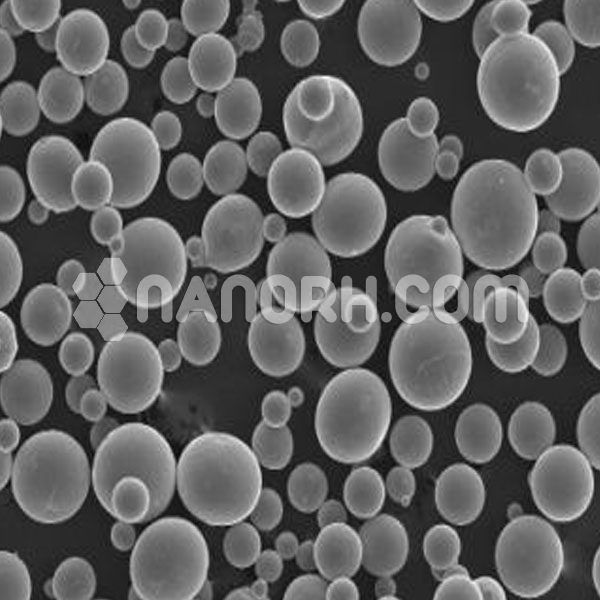

| Shape | spherical | |

| The proportion of Sphere /% | ≥95 | |

| Apparent density /g·cm-3 | 1.236 | |

| Real density /g·cm-3 | 2.1153 | |

| Fluidity /s·(50g)-1 | 53 | |

| Moisture absorption rate /% | 0.01 | |

| Active Mg+Al content /% | 99.25 | |

| Calorific value kJ/g | 23.26 | |

|

Impurity

content

/% |

Moisture/%(max) | 0.05 |

| Insoluble material in HCl /%(max) | 0.13 | |

| Oil & grease /%(max) | 0.00 | |

| Fe/%(max) | 0.05 | |

| Mn/%(max) | 0.01 | |

| Zn/%(max) | 0.01 | |

| Cl/%(max) | 0.003 | |

Atomized spherical Mg-Al alloy powder

Introduction

Atomized spherical Mg-Al (Magnesium-Aluminum) alloy powders are produced by atomizing a molten blend of magnesium and aluminum. The atomization process (usually gas or water atomization) creates fine, spherical particles with a uniform distribution of alloying elements.

Key Features

Spherical Shape:

The spherical shape improves powder flowability, enabling uniform spreading and better packing density in additive manufacturing and other powder-based processes.

Low Density:

Magnesium alloys, in general, are known for their low density, making them ideal for applications where reducing weight is a priority, such as in aerospace and automotive industries.

High Strength-to-Weight Ratio:

Mg-Al alloys offer a high specific strength (strength per unit weight), making them suitable for structural applications where minimizing weight without compromising strength is critical.

Good Corrosion Resistance:

The addition of aluminum to magnesium enhances the material’s corrosion resistance, especially in atmospheric and marine environments, expanding its potential applications.

Improved Processability:

Spherical powders are easy to handle and provide better flowability, making them suitable for powder metallurgy (PM), additive manufacturing, and thermal spraying.

Thermal Conductivity and Damping Properties:

Magnesium alloys generally have high thermal conductivity and good damping properties, making them ideal for applications in thermal management and vibration damping.

Low Thermal Expansion:

Magnesium alloys exhibit low thermal expansion, making them suitable for high-precision applications where dimensional stability under temperature changes is essential.