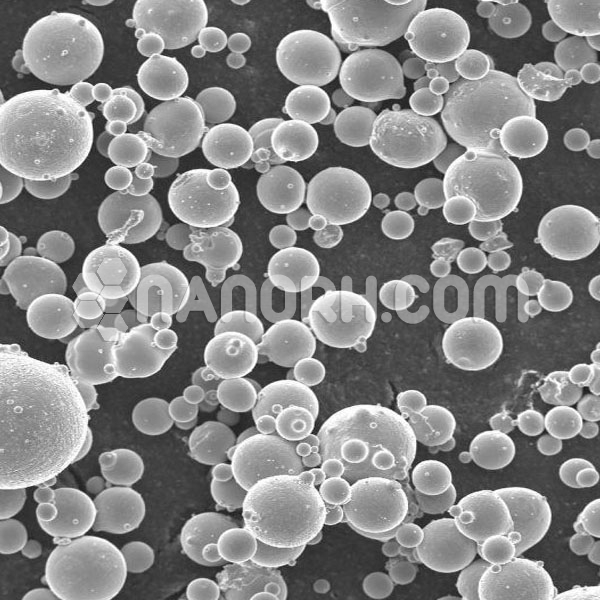

| WE43 alloy powder | |

| Product No | NRE-60102 |

| Purity | 99.9% |

| Mesh | 15-53 mesh |

| Color | Silver Gray |

| WE43 | ||||||||

| Composition | Y | Re | Zr | Fe | Si | Cu | Ni | Mg |

| wt% | 4.01 | 3.04 | 0.51 | 0.00713 | 0.00400 | 0.00370 | 0.00432 | balance |

WE43 alloy powder

Applications

Additive Manufacturing (3D Printing):

WE43 alloy powder is commonly used in additive manufacturing, particularly in techniques like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Laser Powder Bed Fusion (LPBF). These processes enable the production of complex geometries and high-performance parts that require both strength and lightweight properties.

Applications in aerospace, automotive, and defense industries include lightweight structural components, brackets, housing parts, and engine components that require strength, corrosion resistance, and thermal stability.

Aerospace Industry:

WE43 alloy is extensively used in the aerospace industry for engine components, aircraft structural parts, turbine blades, and landing gear. The alloy’s ability to withstand high temperatures, creep resistance, and low weight make it a prime choice for aerospace applications.

Lightweight components contribute to fuel efficiency, payload capacity, and performance while maintaining durability and resistance to wear at high operating temperatures.

Automotive Industry:

In the automotive sector, WE43 alloy powder is used for the production of lightweight components such as engine parts, transmission housings, brackets, and chassis parts. The high strength-to-weight ratio reduces the overall vehicle weight, improving fuel efficiency and vehicle performance.

Electric vehicles (EVs) benefit particularly from the use of WE43 alloy, as the reduction in weight enhances battery life, energy efficiency, and vehicle range.

Medical Devices:

WE43 is used for biodegradable medical implants such as bone plates, pins, screws, and stents. The alloy’s biocompatibility and biodegradability make it an ideal material for temporary implants that degrade naturally as the body heals, reducing the need for removal surgeries.

Additionally, WE43’s high strength and lightweight characteristics are valuable in producing lightweight prosthetic devices or implants.