| WE43 alloy spherical powder | |

| Product No | NRE-60102 |

| Purity | 99.9% |

| Mesh | 15-53 mesh |

| Color | Silver Gray |

| WE43 | ||||||||

| Composition | Y | Re | Zr | Fe | Si | Cu | Ni | Mg |

| wt% | 4.01 | 3.04 | 0.51 | 0.00713 | 0.00400 | 0.00370 | 0.00432 | balance |

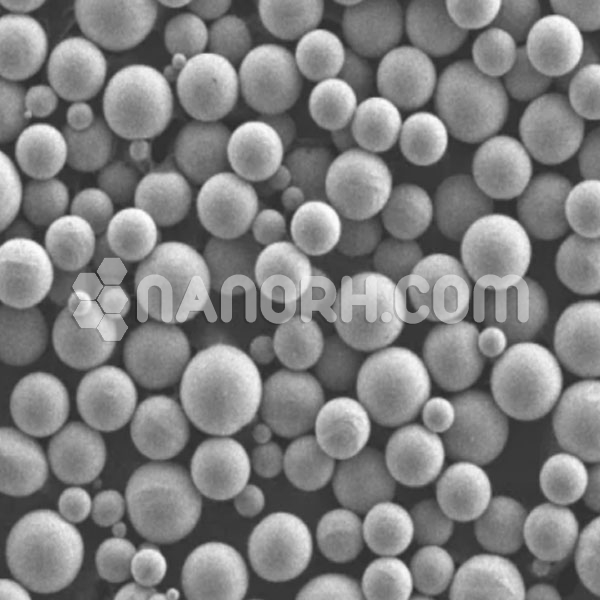

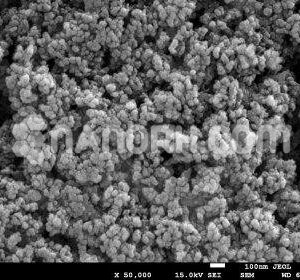

WE43 alloy spherical powder

Introduction

Spherical WE43 alloy powder is a specialized magnesium-based alloy powder that contains rare earth elements like neodymium (Nd), ytterbium (Yb), and praseodymium (Pr), along with zirconium (Zr). This powder is produced using advanced techniques like gas atomization or water atomization, which results in spherical particles that enhance its flowability, packing density, and uniformity. The spherical shape is crucial for applications where precision, consistency, and efficiency in manufacturing processes are essential, such as in additive manufacturing (3D printing), powder metallurgy, and metal injection molding (MIM).

Key Features

Lightweight and High Strength:

WE43 alloy is primarily composed of magnesium, making it significantly lighter than other metals, while the rare earth elements enhance its strength without increasing weight. This makes it ideal for applications in aerospace, automotive, and medical devices, where weight reduction is critical without compromising performance.

Excellent Creep Resistance:

One of the standout features of spherical WE43 alloy powder is its creep resistance at high temperatures. This makes it particularly suitable for components subjected to prolonged stress, such as aircraft engines, turbine blades, and other high-temperature environments.

Corrosion Resistance:

WE43 alloy offers excellent resistance to corrosion, particularly in marine and chemical environments. The spherical powder form further enhances the alloy’s resistance to degradation, ensuring longer-lasting components exposed to saltwater, moisture, and harsh chemicals.

Thermal Stability:

The thermal stability of WE43 alloy allows it to maintain its mechanical properties even when exposed to high temperatures, which is essential for applications in aerospace engines, automotive powertrains, and electronic devices that generate substantial heat.